Attachments – Drum Cutter

Drum Cutter-Single Drum

Single Drum Cutters leverage high power and impact resistance, rendering them irreplaceable in hard-rock mining and water conservancy projects.

| Name | Model | RDC100V | RDC150V | RDC200V |

|---|---|---|---|---|

| Carrier | T | 2.5-6 | 8-15 | 18-30 |

| lbs/pounds | 5512-13228 | 17637-33069 | 39683-66139 | |

| Max Power | KW | 41 | 70 | 110 |

| Rotary Speed | Rpm | 80-160 | 50-100 | 63-100 |

| Oil Flow Range | LPM | 25-40 | 45-85 | 120-150 |

| gpm | 6.6-11 | 12-22 | 32-40 | |

| Torque | N.m | 1858-4960 | 4338-11178 | 9695-16688 |

| Displacement | ml/r | 467-1248 | 1091-2812 | 2439-4198 |

| Cutting Teeth | Pcs | 26 | 32 | 32 |

| Max Pressure | Mpa | 40 | 40 | 40 |

| psi | 5802 | 5802 | 5802 | |

| Weight | Kg | 210 | 750 | 750 |

| A*B*C | mm | 370*430*850 | 450*650*1200 | 450*650*1200 |

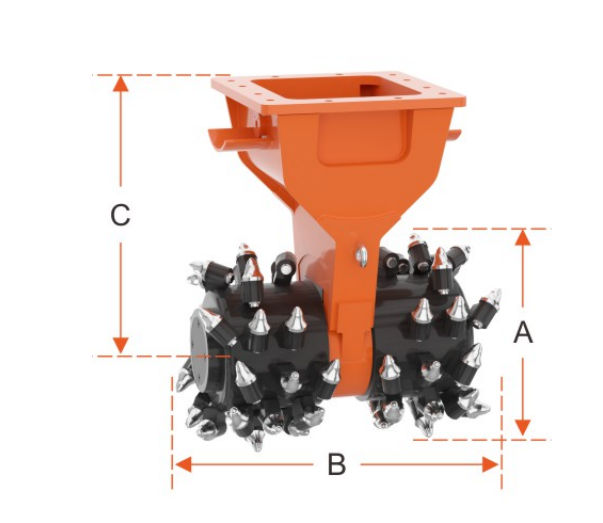

Drum Cutter-Double Drum

Double Drum Cutters excel in flexibility, efficiency, and environmental friendliness, making them the preferred choice for soft-rock tunnels and municipal engineering projects.

| Name | Model | RDC100 | RDC150 | RDC200 | RDC300 | RDC400 |

|---|---|---|---|---|---|---|

| Carrier | T | 3-16 | 12-18 | 18-30 | 25-40 | 25-60 |

| lbs/pounds | 6614-35274 | 26455-39683 | 39683-66139 | 55116-88185 | 55116-132277 | |

| Max Power | KW | 29 | 41 | 70 | 110 | 140 |

| Rotary Speed | Rpm | 100-160 | 80-160 | 50-100 | 63-100 | 50-80 |

| Oil Flow Range | LPM | 40-125 | 90-125 | 120-150 | 130-240 | 130-190 |

| gpm | 11-33 | 24-33 | 32-40 | 34-63 | 34-50 | |

| Torque | N.m | 1033-3260 | 1858-4960 | 4338-11178 | 9695-16688 | 13913-23893 |

| Displacement | ml/r | 260-820 | 467-1248 | 1091-2812 | 2439-4198 | 3500-6011 |

| Cutting Teeth | Pcs | 44 | 44 | 48 | 48 | 56 |

| Max Pressure | Mpa | 40 | 40 | 40 | 40 | 40 |

| psi | 5802 | 5802 | 5802 | 5802 | 5802 | |

| Weight | Kg | 381 | 580 | 1370 | 1400 | 1800 |

| A*B*C | mm | 420*740*585 | 420*780*615 | 420*1060*830 | 420*1155*830 | 420*1350*875 |

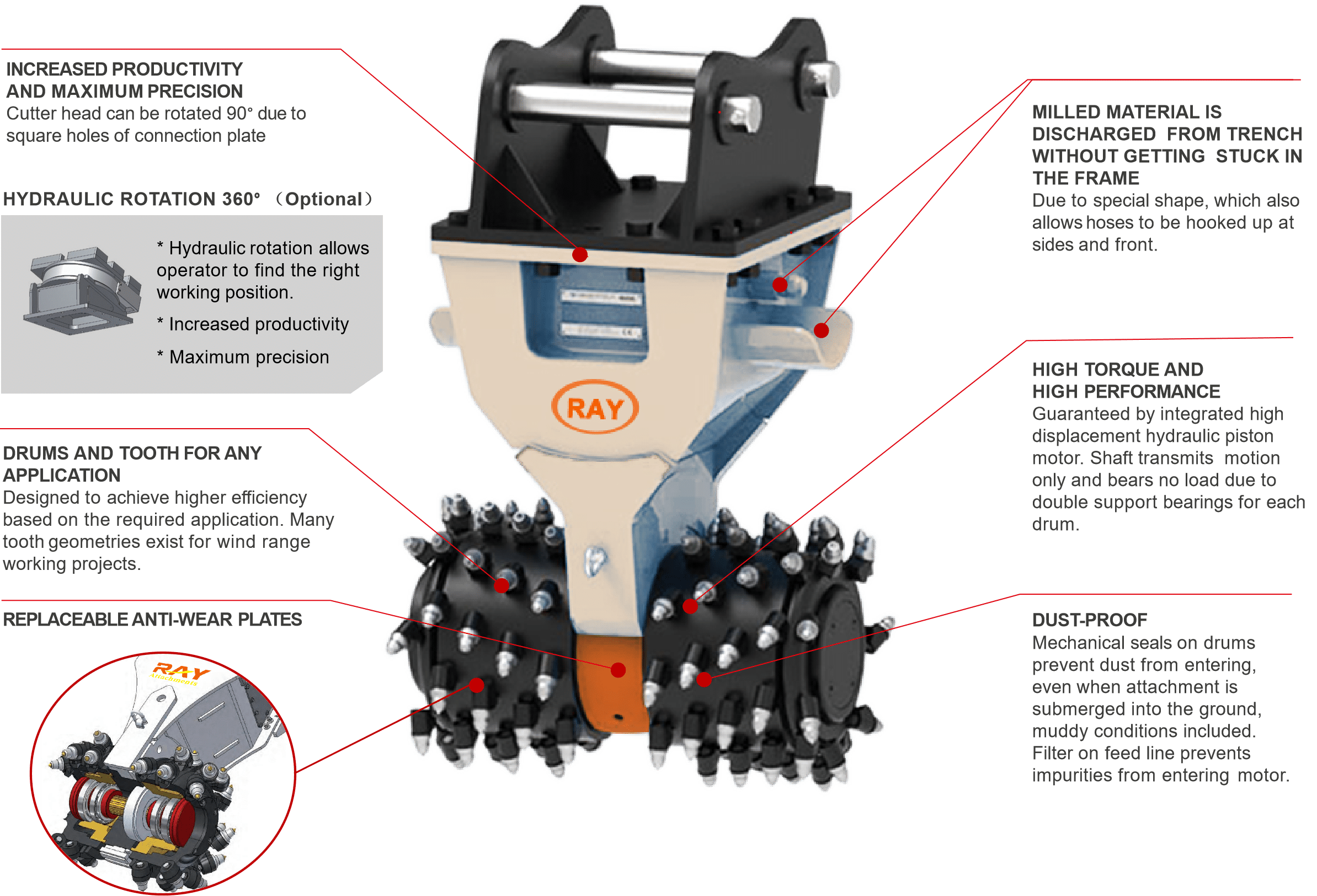

Drum Cutter Features

- Increased Productivity And Maximum Precision: Cutter head can be rotated 90° due to square holes of connection plate.

- Hydraulic Rotation 360° (Optional)

- Drums And Tooth For Any Application: Designed to achieve higher efficiency based on the required application. Many tooth geometries exist for wind range working projects.

- Replaceable Anti-Wear Plates

- Milled Material Is Discharged From Trench Without Getting Stuck In The Frame: Due to special shape, which also allows hoses to be hooked up at sides and front.

- High Torque And High Performance: Guaranteed by integrated high displacement hydraulic piston motor. Shaft transmits motion only and bears no load due to double support bearings for each drum.

- Dust-Proof: Mechanical seals on drums prevent dust from entering, even when attachment is submerged into the ground, muddy conditions included. Filter on feed line prevents impurities from entering motor.

About

RAY Attachments

Founded in 2002, RAY began with the production of steel pipes and evolved into a profound understanding of excavator needs. Initially engaged in trade, we were among the pioneers in bringing Chinese manufacturing excellence to the world and introducing hydraulic breakers to the international market. Our first international client, Mr. Yousaf, came from Qatar in 2009, marking the beginning of many successful collaborations.

Hassle-Free Warranty

12 months – 36 months (option)

One-stop Shopping

Save your 30% cost at least

Save 50% time

Quick Response

2 hours response

Provide the solution within 12 hours

Business Support

Customer multiplier plan

Featured Videos

Frequently asked questions

REQUEST A QUOTE

Can’t find the answer you’re looking for?

Complete our quote request form or email us at raysales1@rayattachments.com to receive a customized quote from our product specialists.