What is pile breaker?

Pile breaking involves demolition of old concrete piles in order to make way for driving of new piles and subsequent building of new structures. Demolition of concrete piles is quite a challenge due to the presence of steel reinforcement bars and using conventional methods of can be quite cumbersome and time-consuming.

In construction project involving pile foundations, one of the most cumbersome and time consuming activity is the crushing of top portion of the Castin-Situ Piles /Precast Piles as required to remove the weak top concrete and expose the reinforcement to be used for further construction. Pile breakers solve the problem by crushing such overhangs in a speedy and precise way. The reinforcement bars are left intact facilitating the rebuilding work. The breaking down of concrete piles is an essential part of the construction process and a subject that is often not given sufficient early thought in the planning of the piling works.The adoption of a suitable pile breaking method can result in financial savings for the project and most importantly will address and reduce potential health and safety issues in relation to this phase of the works.

Why do you need?

Environment-friendly

Its full hydraulic drive causes little noises during operation and no influence on the surrounding environments.

Low-cost

The operating system is easy and convenient. Fewer operating workers are required to save money for labor and machine maintenance during construction

Multi-function

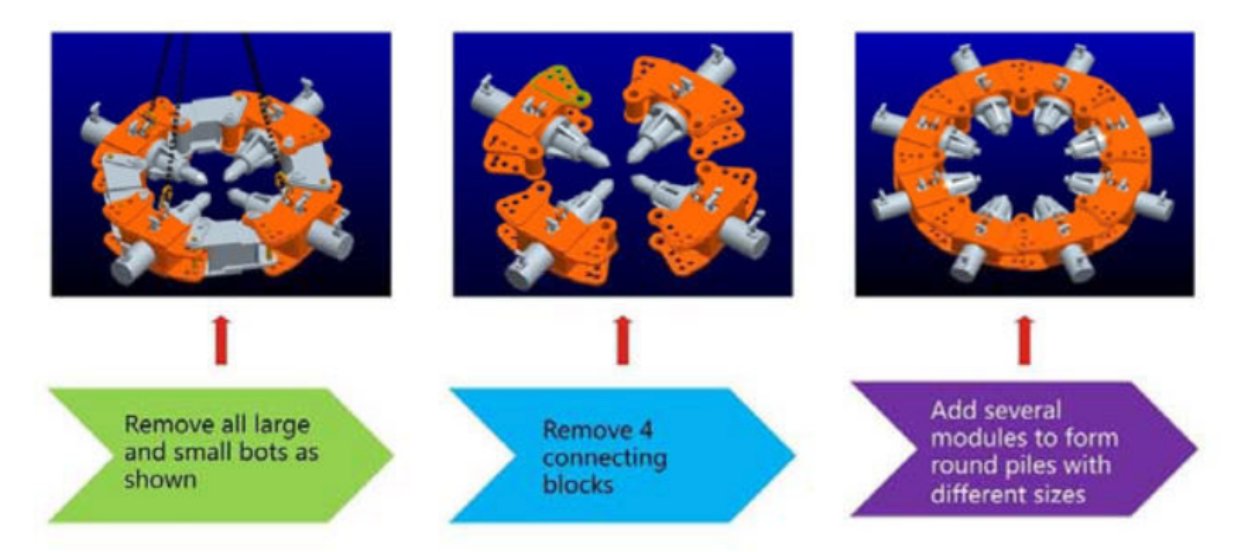

Module generalization is realized with our SP400 square pile machine it can be used for both circular piles and square piles by changing the module combination.

Small volume

It’s light for convenient transportation.

Safety

Contact-free operation is enabled and it can be applied for construction on complex landform.

Universal property

It can be driven by diverse power sources and is compatible with excavators or hydraulic system according to the construction sites conditions. It is flexible to connect multiple construction machines with universal and economical performance. The telescopic sling lifting chains meet the requirements of various landforms.

Why choose us?

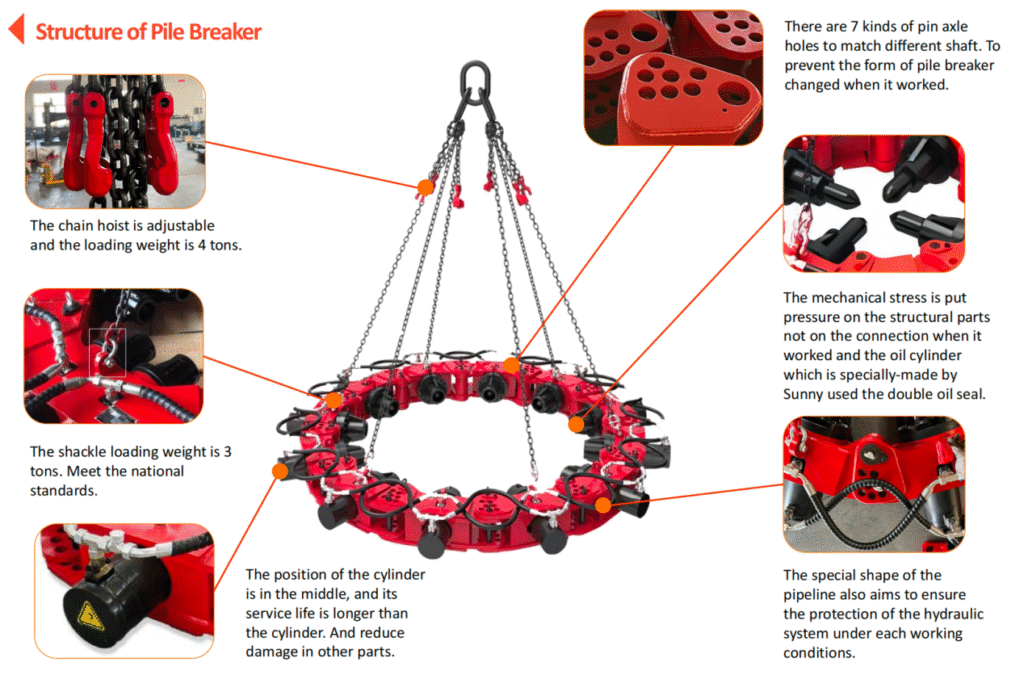

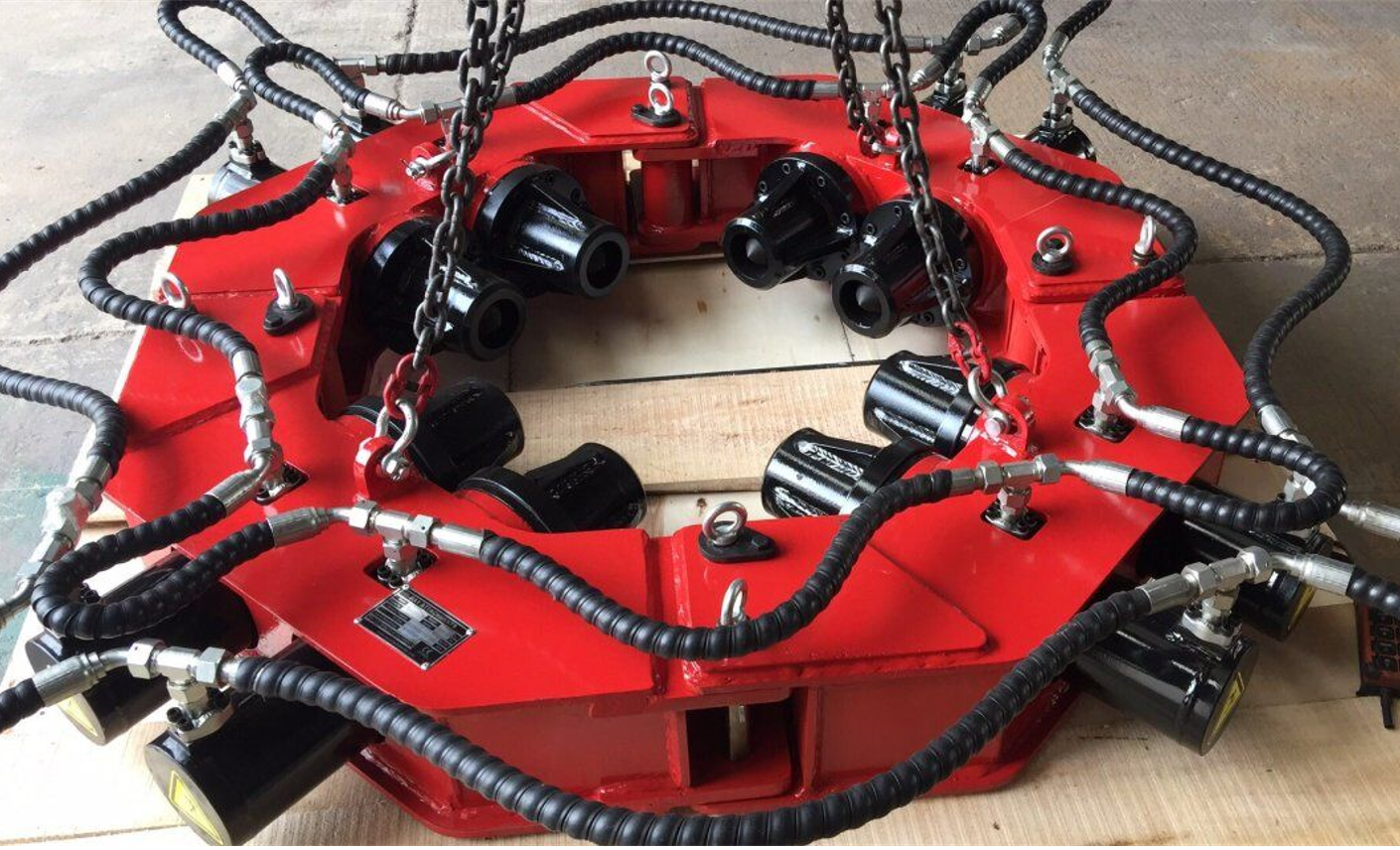

The cylinder position is in middle and has a longer service life than cylinder position is in rear. And reduce the damage to other parts.We use 42CrMo material. It’s more durable We provide 30pcs elastic pin for free. Virtually silent operations for environmentally friendly sites.

The special shape of the pile breaker is also designed to ensure the protection of the hydraulic system in every working condition.Each module is supplied with one cylinder tip, easy to carry up when add or remove module.

How to choose right model?

For square piles

We have SP400, SP500, SP600 (square piles) Suitable for 300-550mm square piles.

SP400 (light duty)

SP500 (light duty)

SP600 (heavy duty)

| Model | Unit | SP400(Light) | SP500(Light) | SP600(Heavy) |

|---|---|---|---|---|

| Range of pile breaker | mm | 300-400 | 400-500 | 300-550 |

| Max force for single rod | KN | 320 | 320 | 790 |

| Max stroke of hydraulic cylinder | mm | 150 | 150 | 205 |

| Pressure of hydraulic cylinder | Mpa | 34.3 | 34.3 | 34.3 |

| Max flow for single cylinder | L/min | 25 | 25 | 25 |

| Max height for each crush | mm | ≤300 | ≤300 | ≤300 |

| Suitable carrier | T | ≥8 | ≥15 | ≥20 |

| Single moulde weight | kg | 110 | 220 | 400 |

| Single module size | mm | 604*594*286 | 595*980*275 | 910*780*400 |

| Dimensions at working | mm | 1600*1600*2000 | 1710*1710*2500 | 2050*2050*2000 |

| Total pile breaker weight | kg | 650 | 950 | 2000 |

| Item | Detailed | |

| Model | SP400,SP500 light duty | SP600 heavy duty |

| Weight | 110kg | 400kg |

| Pile range | 400-500mm square | 300-550mmsquare |

| Cylinder Qty | 8pcs | 4pcs |

| Max force for single rod | 320KN | 790KN |

| Cylinder stroke | 150mm | 205mm |

| Chisel size | 75*220mm | 125*310mm |

| The thickness for module | 250mm | 350mm |

| Cut the no.of piles(8 hours) | 120pcs | 160-100pcs |

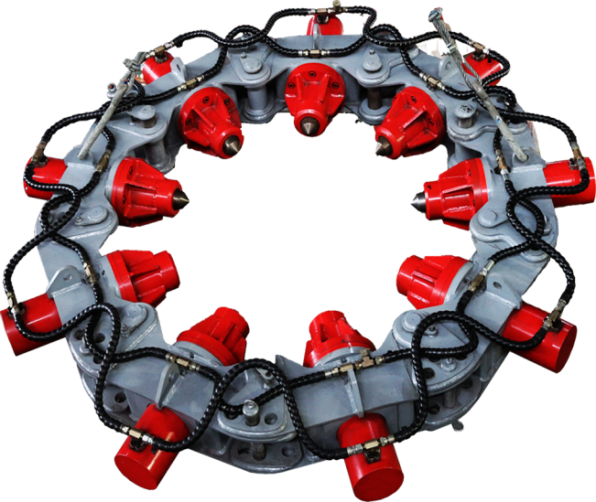

For round piles

SP380, SP800 (round piles) Suitable for 300-2000mm round piles.

RAY pile breaker (380-Round)

The Round pile SP380 light duty pile breaker: Suitable for 300-1050mm round pile.

| Model | Unit | SP380 |

| Moduld number | modules | 7-12 |

| Range of pile breaker | mm | 300-400 |

| Max force for single rod | KN | 350 |

| Max stroke of hydraulic cylinder | mm | 150 |

| Pressure of hydraulic cylinder | Mpa | 32-35 |

| Max flow for single cylinder | L/min | 25 |

| Max height for each crush | mm | ≤300 |

| Suitable carrier | T | 12 |

| Single moulde weight | kg | 110 |

| Total pile breaker weight | kg | 920 |

| Model | Unit | SP380 (Light duty) | |||||

| Moduld number | modules | 7 | 8 | 9 | 10 | 11 | 12 |

| Range of pile breaker | mm | 300-400 | 450-500 | 550-625 | 650-750 | 800-900 | 900-1050 |

| Suitable carrier | T | 12 | 13 | 15 | 18 | 21 | 26 |

| Total pile breaker weight | kg | 920 | 1030 | 1140 | 1250 | 1360 | 1470 |

| Height of single crush pile | mm | 300 | 300 | 300 | 300 | 300 | 300 |

RAY pile breaker (SP800)

The Round pile SP800 light duty pile breaker: Suitable for 500-2000mm round pile.

| Model | Unit | SP800 |

|---|---|---|

| Moduld number | modules | 6-13 |

| Range of pile breaker | mm | 1050-1200 |

| Max force for single rod | KN | 650 |

| Max stroke of hydraulic cylinder | mm | 215 |

| Pressure of hydraulic cylinder | Mpa | 32-35 |

| Max flow for single cylinder | L/min | 25 |

| Max height for each crush | mm | ≤300 |

| Suitable carrier | T | 27 |

| Single moulde weight | kg | 380 |

| Total pile breaker weight | kg | 3480 |

| Model | Unit | SP800(Heavy duty) | |||||||

| Moduld number | modules | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| Range of pile breaker | mm | 500-600 | 650-800 | 850-1000 | 1050-1200 | 1250-1400 | 1450-1600 | 1650-1800 | 1850-2000 |

| Suitable carrier | T | 20 | 22 | 26 | 27 | 30 | 32 | 35 | 36 |

| Total pile breaker weight | kg | 2335 | 2720 | 3100 | 3480 | 3860 | 4240 | 4620 | 5000 |

| Height of single crush pile | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Item | Detailed | |

| Model | SP380 light duty | SP800 heavy duty |

| Weight | 110kg | 380kg |

| Pile range | 300-1050mm round | 500-2000mm round |

| Max force for single rod | 320KN | 790KN |

| Cylinder stroke | 150mm | 205mm |

| Chise size | 75*220mm | 125*310mm |

| The thickness for module | 250mm | 350mm |

| Cut the no.of piles(8 hours) | 40-60pcs | 40-100pcs |

This is the difference between light and heavy duty. You just need to choose according to your concrete strength and diameter.

If you turn a square pile into a round pile

How to operate and maintain a pile breaker?

Safety Precautions

- Please read this manual thoroughly before installing, debugging, using and repairing this device.

- The operator must have been trained strictly and obtained certificate before operating the device

- All the provisions of this manual must be strictly followed in the course of use and maintenance.

- The auxiliary products of this device controlled and managed with safety signs must also have safety signs. So do the replacing parts during the usage.

- No person is allowed to stand in the working device in the course of the hydraulic Pile Breakers being installed, debugged, used or repaired.

- Safety warnings must be carried out before the start of the engineering machine.

Says that if neglecting these instructions, improper operations may cause personal casualties or severe device damage.

Says that if neglecting these instructions, improper operations may cause personal injury or device damage.

Says that if neglecting these instructions, improper operations may cause mild personal injury or device trouble.

Says that only qualified personnel are allowed to install and operate this device. In this manual, qualified personnel are people who are authorized to install, debug, use and repair the device according to the existing safety regulations and standard.

Overview of SP Series Full-hydraulic Pile Breakers

SP380 pile breaker (light duty round)

SP380 pile cutter usage environment:

- Pile cutter construction requires a power source, which can be a fixed pump station or other movable engineering machinery and equipment;

- The hydraulic system pressure is 31.4MPa, the overflow valve setting value is 34.4MPa, the main hydraulic pipe is 20mm in diameter, and the cylinder oil pipe is 16mm;

- There are uncertain factors in the composition of engineering machinery and pile foundation materials. The maximum depth of each pile cut is 0.3 meters;

- When the power source uses engineering machinery, the number of modules and the range of pile diameters, the required tonnage of engineering machinery, and the weight of the whole machine

SP800 pile breaker (heavy duty round)

SP800 pile cutter usage environment:

- Pile cutter construction requires a power source, which can be a fixed pump station or other movable engineering machinery and equipment;

- The hydraulic system pressure is 31.4MPa, the overflow valve setting value is 34.4MPa, the main hydraulic pipe is 25mm in diameter, and the cylinder oil pipe is 20mm;

- There are uncertain factors in the composition of engineering machinery and pile foundation materials. The maximum depth of each pile cut is 0.3 meters;

- When the power source uses engineering machinery, the number of modules and the range of pile diameters, the required tonnage of engineering machinery, and the weight of the whole machine

SP400 pile breaker (light duty square)

SP400 pile cutter operating environment:

- Pile cutter construction requires a power source, which can be a fixed pump station or other movable engineering machinery and equipment;

- The hydraulic system pressure is 31.4MPa, the overflow valve setting value is 34.4MPa, and the hydraulic pipe has a diameter of 16mm;

- There are uncertain factors in the composition of engineering machinery and pile foundation materials. The maximum depth of each pile cut is 0.3 meters;

- The applicable engineering machinery tonnage is 8-12 tons, the side length of the pile cut is 400-200mm, and the weight of the whole machine is 0.75 tons.

SP500 pile breaker (light duty square)

SP500 pile cutter use environment:

- Pile cutter construction requires a power source, which can be a fixed pump station or other movable engineering machinery and equipment;

- The hydraulic system pressure is 31.4MPa, the overflow valve setting value is 34.4MPa, and the hydraulic pipe has a diameter of 16mm;

- There are uncertain factors in the composition of engineering machinery and pile foundation materials. The maximum depth of each pile cut is 0.3 meters;

- Applicable engineering machinery tonnage is 12-15 tons, the side length of the pile cut is 500-400mm, and the weight of the whole machine is 0.9 tons.

Installation and operation instructions

Determine and install the corresponding number of modules and lifting devices, and the pile cutter can be used when it is delivered to the customer, saving the customer’s initial operation time. In engineering construction, mobile excavators are often used as power sources. Remove the excavator bucket, hang the pile cutter’s lifting chain at the connecting shaft between the bucket and the boom, and mechanically combine the two equipment together. Then connect the excavator’s boom hydraulic oil circuit to the pile cutter’s cylinder oil circuit through a balance valve to drive the pile cutter’s cylinder group to work.

How to connect pile breaker to excavator ?

1. Please find the third picture (Red rectangle part, you have to find it in local market, because different excavator connect method is little different).

2. Buy the part in a red rectangle, fit it to excavator and connect it with part in a green rectangle. (Please check below picture).

3. See below picture (connector on cylinder body, it connects input line, the other is output line).

4. Below is hose in another size.

Operation precautions

- Do not approach the pile cutter in operation. Concrete will fall when cutting piles. Before approaching the pile cutter, you must notify the power source operator to stop the operation!

- Check whether the hydraulic oil pipes and hydraulic joints are tightened before cutting piles. When the hydraulic pipes are tightened, the oil pipes and joints with oil leakage must be replaced!

- The working device part must not be knocked or damaged by external force, which will affect the use of the working device and the life of the whole machine. The working device must be cleaned frequently after cutting piles!

- No one should be within the rotation range of the construction machinery during the pile cutting operation, otherwise it will cause serious casualties!

- During transportation, site transfer and operation, no external force should be used to knock or press the oil cylinder! When the construction is stopped, the dirt, broken sand, etc. of the oil cylinder accessories should be removed frequently to keep the area around the oil cylinder clean!

- Hydraulic pipes and pipe joints must not be knocked or pressed by external force during transportation and operation at the construction site! Especially when operating, if there are pieces of concrete falling on the hydraulic parts, remove the concrete on the hydraulic parts when not in operation, keep the hydraulic parts from being deformed by external forces, and keep the area around the hydraulic parts clean!

- When working, please ensure that the drill rod of the round pile cutter is tangent to the pile (the drill rod of the square pile cutter is at a vertical angle to the pile) to avoid the drill rod of the pile cutter and the pile forming an angle, which may damage the machine!

Maintenance Instructions

Hydraulic pile cutters are easy to repair and maintain. When the pile cutter works continuously for 1 month or cuts 1,000 piles, stop the operation and check whether all parts of the pile cutter are intact?

First check whether the lifting device is damaged or cracked, especially the lifting chain and chain shackle. Carefully check each part. If there is damage or crack, please replace it immediately! Check the working device, especially the drill rod and hydraulic parts!

The drill rod is a direct working part. When a certain workload is reached, it is easy to break. Pressurize and extend all the drill rods. Check each drill rod one by one. If there is damage or crack, please replace it immediately. If it is intact; each hydraulic part should also be checked one by one. If there is damage or crack, update it immediately.

Key points of daily maintenance

After completing work every day, the air pump air pipe needs to be aligned with the gap between the guide flange and the drill rod to clean the air inward (as shown in the figure below). This will blow out the dust entering the guide flange, which is good for the maintenance of the drill rod, guide flange and cylinder.