What is an Excavator Hydraulic Breaker?

What is a Hydraulic Breaker?

A hydraulic breaker, also known as a hydraulic hammer, is a percussion demolition tool designed to break hard materials like rock, concrete, or asphalt. It is typically mounted on excavators, skid steer loaders, or backhoes and powered by the machine’s hydraulic system.

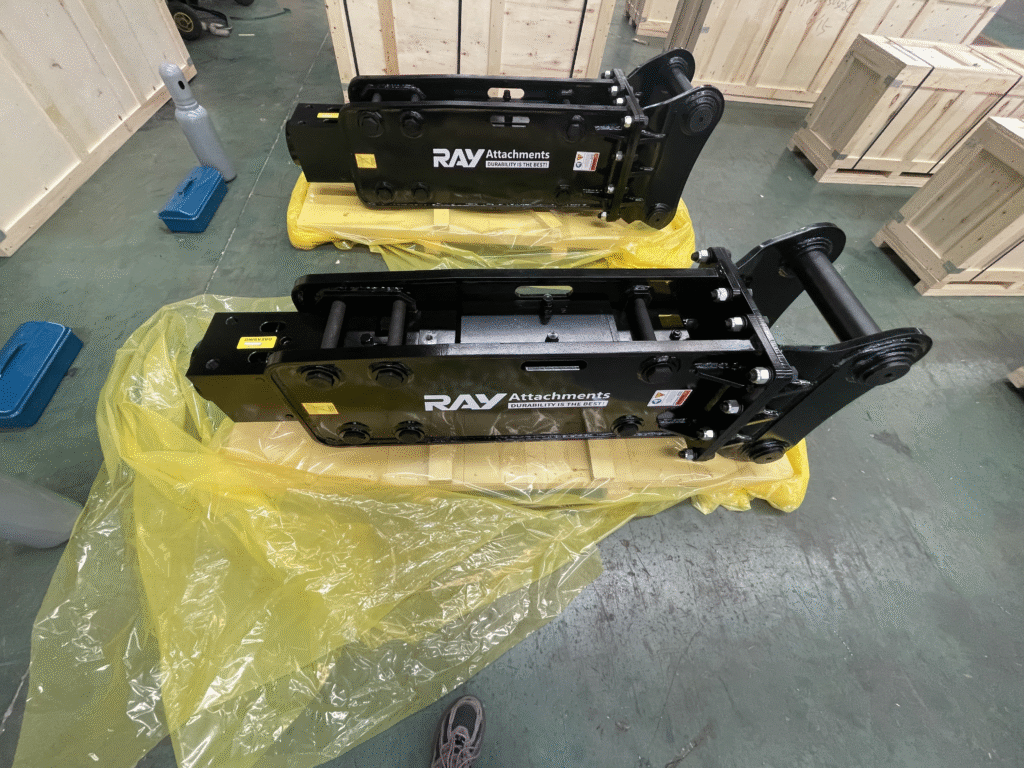

Benefits of RAY Hydraulic Breakers:

- High impact energy with nitrogen gas assist

- Broad model range for 0.8–70 ton excavators

- Easy-to-maintain structure

- CE certified & export-ready

Our RHB series hydraulic breakers are widely used in construction, quarrying, demolition, mining, and roadwork projects.

Types of Hydraulic Breakers We Offer

RAY offers multiple models of breakers designed for different applications and carrier sizes:

| Model | Tool Dia[mm] | Carrier Weight[ton] | Impact Frequency[bpm] |

|---|---|---|---|

| RHB40–RHB53 | 40–53 | 0.8–3.5 | 500–1200 |

| RHB68–RHB85 | 68–85 | 4–14 | 400–800 |

| RHB100–RHB125 | 100–125 | 10–18 | 350–700 |

| RHB135F–RHB210 | 135–210 | 20–55 | 300–500 |

Types by Structure:

- Top Type: Excellent alignment and deeper penetration

- Side Type: Lightweight, cost-efficient

- Box Type: Noise-reduced, ideal for urban zones

- Banana Type: Curved design allows vertical impact even when working close to the rear wheels or walls and convenient storage.

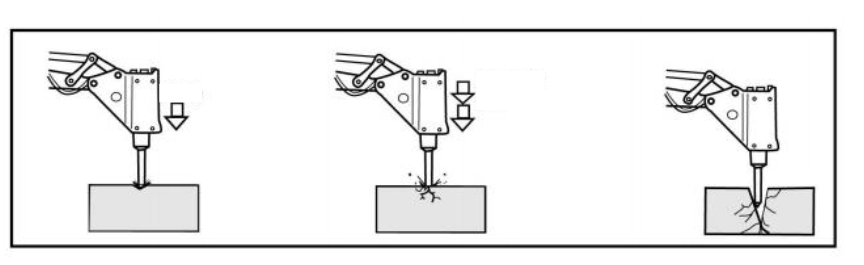

How Does a Breaker Work?

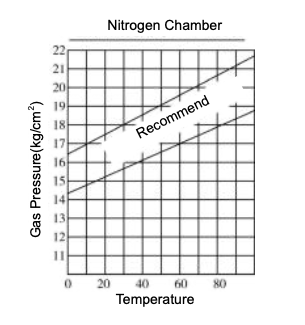

A hydraulic breaker uses the flow of pressurized hydraulic oil to power a piston that strikes the chisel at high frequency. RAY breakers incorporate nitrogen chambers to amplify the impact force, delivering efficient power with minimal recoil.

Main Components:

- Nitrogen chamber: Boosts energy

- Hydraulic piston: Delivers impact

- Tool/chisel: Breaks material

- Main valve: Controls oil flow

- Accumulator (for larger models): Stabilizes pressure

Applications & Compatible Attachments

Hydraulic breakers are commonly used in:

- Demolishing concrete foundations

- Breaking hard rock or frozen ground

- Tunnel or trench excavation

- Road construction & repair

On the same job site, RAY also offers:

- Quick Hitch: For fast tool change without manual pin removal

- Crusher Bucket: For on-site crushing of concrete blocks or bricks

- Drum Cutter: For accurate profiling of walls and roads

- Vibro Ripper: For fast breaking of medium-hard rock and permafrost

Choose attachments based on job requirements—breakers for impact, rippers for fast penetration, and buckets for recycling.

How to Choose the Right Hydraulic Breaker

When selecting a breaker, consider:

| Factor | What to Look For |

|---|---|

| Carrier Tonnage | Match breaker size to machine weight |

| Hydraulic Flow & Pressure | Must match breaker specs |

| Application Type | Concrete? Rock? Underwater? Urban? |

| Noise Requirements | Use Box Type in cities |

| Tool Options | Moil, conical, blunt, wedge types |

| Operating Hours | Select high-duty model for frequent use |

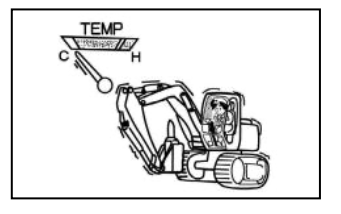

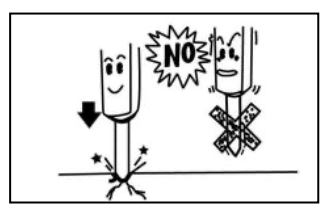

Operation Precautions

To extend the life of your breaker and ensure safety:

✅ Always warm up hydraulic oil before operation

✅ Position tool perpendicular to the working surface

✅ Regularly lubricate the tool shank

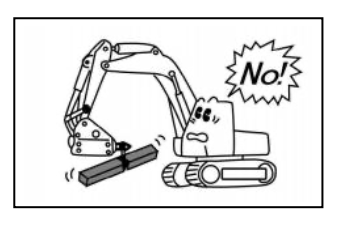

❌ Avoid blank firing (firing without material contact)

❌ Do not use as a lifting or prying device

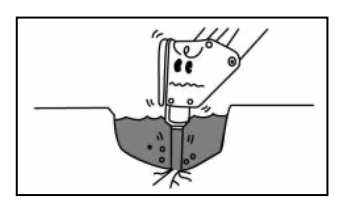

❌ Do not operate in water unless using a waterproof kit

Tip: Use a grease gun every 2 hours of operation to prevent bushing wear.

Maintenance & Customer FAQs

RAY Breakers are designed for easy maintenance:

- Replace hydraulic oil every 800 hours

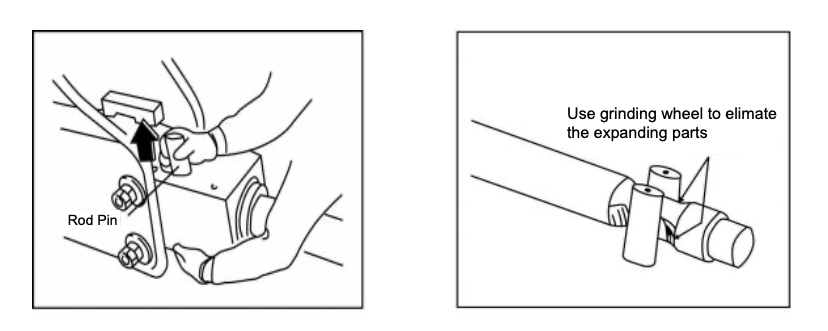

- Check tool wear, rod pin, bolts every 2–3 days

Chisel and Rod Pins

If the pressure is not enough, or the working objects are fragile when the breaker is working, the chisel and rod pins will be deformed and expanded. During inspection, please use the grinding wheel to polish in order to eliminate the expanding parts, or use the rod pin in return.

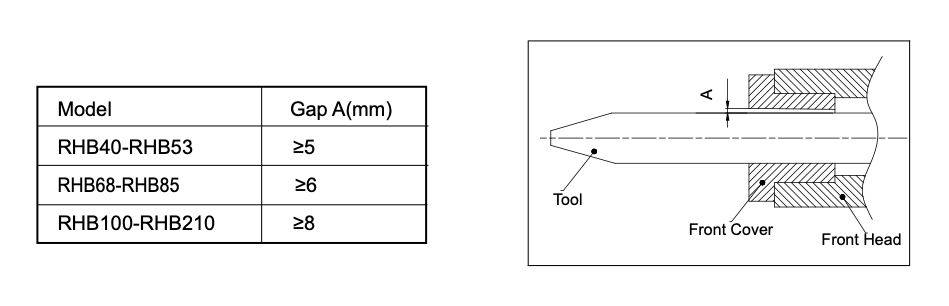

Chisel and Front Cover

If the gap between chisel and front cover is oversized, it will cause eccentric wear of piston and chisel, and lead to their unsteady contact, further causing the damage of piston and chisel, and the chisel turns fragile. When the gap is oversized, the front cover must be changed. Detailed standards of replacement are as follows:

Inspect nitrogen gas pressure every 2 weeks

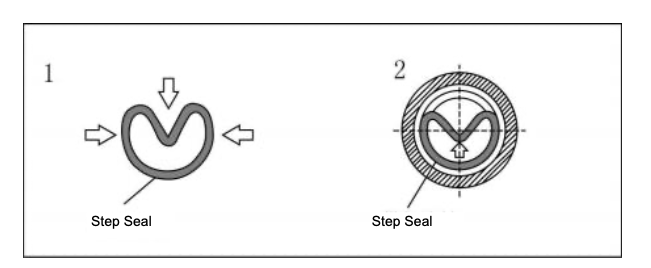

Watch for oil leaks or seal failures

Avoid using worn-out chisels—they damage pistons