Hydraulic Compactor: A Complete Guide: From Basics to Selection & Installation

What is a Hydraulic Compactor? How does it work?

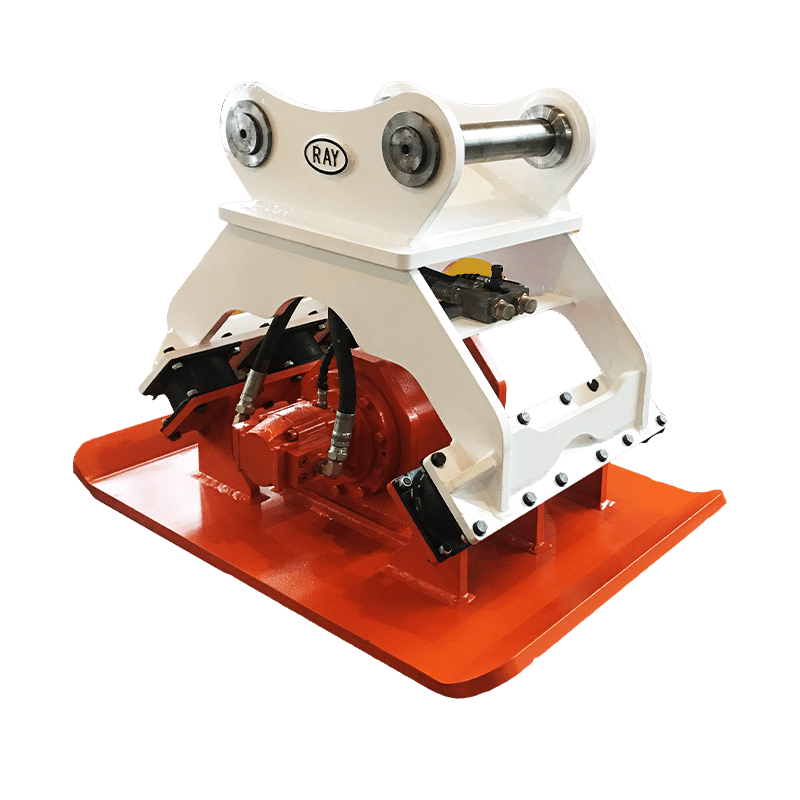

Hydraulic compactor is an engineering machinery that uses a hydraulic system to compact soil, sand and gravel and other materials.

The hydraulic system drives the compactor to rise to the set height, accumulating gravitational potential energy. The hydraulic valve instantly switches the oil circuit, and the rammer falls freely under the dual action of its own weight and hydraulic boost. When the compactor contacts the buffer pad, the kinetic energy is transmitted to the compactor plate through the multi-stage shock absorbing device.

The compactor plate hits the ground, and the generated shock wave propagates deep into the soil in the form of a stress wave, forcing the soil particles to overcome frictional resistance and displace, thereby achieving a compaction effect.

What are the advantages of a Hydraulic Compactor?

Highly adaptable, flexible, and efficient

Commonly used as an accessory for excavators, loaders, and other equipment, it can be directly mounted on standard adapter plates or quick-connect systems, eliminating the need for specialized power equipment. Leveraging the main unit’s maneuverability, it easily accesses confined spaces (such as pipeline backfill areas, wall edges, and slopes). Select models feature a continuous rotation mechanism for 360° adjustment of the working angle, significantly improving efficiency in complex terrain.

Precise and controllable compaction results

The hydraulic system adjusts the tamping frequency and force, allowing for flexible adjustment to suit different soil types (such as sand, clay, and backfill) and compaction requirements. This ensures uniform compaction from the surface to a specific depth, effectively avoiding over- or under-compaction and ensuring the stability of foundations or backfill areas.

Wide operating range

It is suitable for a wide range of applications, including roadside slopes, bridge abutment backs, pipe trench sides, construction pit backfill, indoor ground bases, and other areas difficult to reach with traditional large-scale compaction equipment. It offers irreplaceable advantages for compacting narrow spaces and corners.

Low noise, environmentally friendly, and highly safe

Compared to traditional vibratory rollers and other equipment, hydraulically driven rollers produce lower operating noise, reducing noise pollution to the surrounding environment and making them more suitable for use in noise-sensitive areas such as urban areas and residential areas. Furthermore, equipment operation is performed from the main machine’s cab, keeping the operator away from the worksite, reducing the risk of accidents and improving operational safety.

Multi-functional integration saves costs

When a hydraulic plate compactor is installed on a main machine (such as an excavator), it can simultaneously perform compaction operations while completing excavation and handling tasks. This eliminates the need for frequent equipment replacement, reduces equipment purchase and rental costs, and saves time on equipment transfer and commissioning, thereby improving overall construction efficiency.

Compact structure and easy maintenance

The equipment is relatively compact and features a simple structural design. Core components (such as the hydraulic motor and tamping plate) are easily accessible for inspection and maintenance, resulting in a low failure rate, reducing downtime for repairs and ensuring construction progress.

3. What are the application areas of a Hydraulic Compactor?

It is widely used in compaction operations of soil, embankments, ditches, sheet piles and piles in construction projects. It plays an important role in road construction, building foundation treatment, municipal engineering and other fields. It can improve the bearing capacity of the foundation, reduce post-construction settlement and ensure project quality.

4. How to select a Hydraulic Compactor?

You can use the table below to preliminarily determine the appropriate model based on your excavator’s tonnage.

Of course, to better determine the matching model, you’ll also need to confirm the excavator’s model, age, project conditions, and other factors.

| Model | Unit | RHC-MINI | RHC-04 | RHC-06 | RHC-08 | RHC-10 |

|---|---|---|---|---|---|---|

| Suitable carrier | ton | 3~4 | 5~9 | 10~17 | 18~24 | 25~32 |

| lbs/pounds | 6614~8818 | 11023~19842 | 22046~37478 | 39683~52911 | 55116~70548 | |

| Impact force | ton | 3 | 4 | 6.5 | 15 | 15 |

| lbs/pounds | 6614 | 8818 | 14330 | 33069 | 33069 | |

| Max. Number for Vibration | rpm | 2000 | 2000 | 2000 | 2000 | 2000 |

| Oil flow | l/min | 30-60 | 45-75 | 85-105 | 120~170 | 120~170 |

| gpm | 7.92 – 15.85 | 11.89−19.81 | 22.45−27.74 | 31.70 – 44.91 | 31.70 – 44.91 | |

| Pressure | Kg/cm² | 100-130 | 110-140 | 150-170 | 160-180 | 160-180 |

| Weight | Kg | 200 | 300 | 600 | 850 | 900 |

| lbs/pounds | 440.92 | 661.39 | 1322.77 | 1873.93 | 1984.16 | |

| Impact size (LxW) | mm | 590*420 | 900*550 | 1160*700 | 1250*900 | 1250*900 |

| inch | 23.23*16.54 | 35.43*21.65 | 45.67*27.56 | 49.21*35.43 | 49.21*35.43 | |

| Total height | mm | 435 | 730 | 900 | 1000 | 1050 |

| inch | 17.13 | 28.74 | 35.43 | 39.37 | 41.34 | |

| Total width | mm | 442 | 550 | 700 | 900 | 900 |

| inch | 17.4 | 21.65 | 27.56 | 35.43 | 35.43 | |

| * These specifications are subject to change without prior notice for the improvement of quality. | ||||||

5. Installation of a Hydraulic Compactor

Connection

The next step is to connect the inlet and outlet ends to the flow control valve.

| Inlet and outlet port size | ||

| Model | Inlet | Outlet |

| RHC MINI | 1” (PF) | 1” (PF) |

| RHC 04 | 1” (PF) | 1” (PF) |

| RHC 06 | 1 1/4” (PF) | 1 1/4” (PF) |

| RHC 08 | 2” (PF) | 2” (PF) |

| RHC 10 | 2” (PF) | 2” (PF) |

Settings and adjustments

The flow control valve on the hydraulic vibrating rammer has been set at the factory. If it is used on an excavator that does not match the model, it needs to be set and adjusted by yourself. The method is as follows:

- Remove the pipes from the motor and replace them with a flow meter;

- Apply gentle, moderate pressure on upper arms;

- Pass the oil through the flow meter and adjust the flow control valve. The following is the recommended oil flow rate:

| Model | Set value |

|---|---|

| RHC MINI | 30~60 lpm at 100~130(kg/cm²) |

| RHC 04 | 45~75 lpm at 110~140 (kg/cm²) |

| RHC 06 | 85~105 lpm at 150~170 (kg/cm²) |

| RHC 08 | 120~170 lpm at 160~180 (kg/cm²) |

| RHC 10 | 120~170 lpm at 160~180 (kg/cm²) |

Please keep the pressure as low as possible, which will extend the life of the sealing ring; The manufacturer recommends not exceeding 7bar.

Notice:

If the above inspection is complete, you can start the excavator and slowly extend the forearm to ensure that there is no pinch in the pipeline. Please enable small tamping force first and turn on the oil flow.