Comprehensive Guide To hydraulic shear

What is hydraulic shear or crusher?

Excavator shears/crushers are multifunctional hydraulic attachments mounted on excavators, primarily used in building demolition, scrap processing, and metal recycling. Based on different working conditions, we offer the following five product series to meet various shearing and crushing requirements:

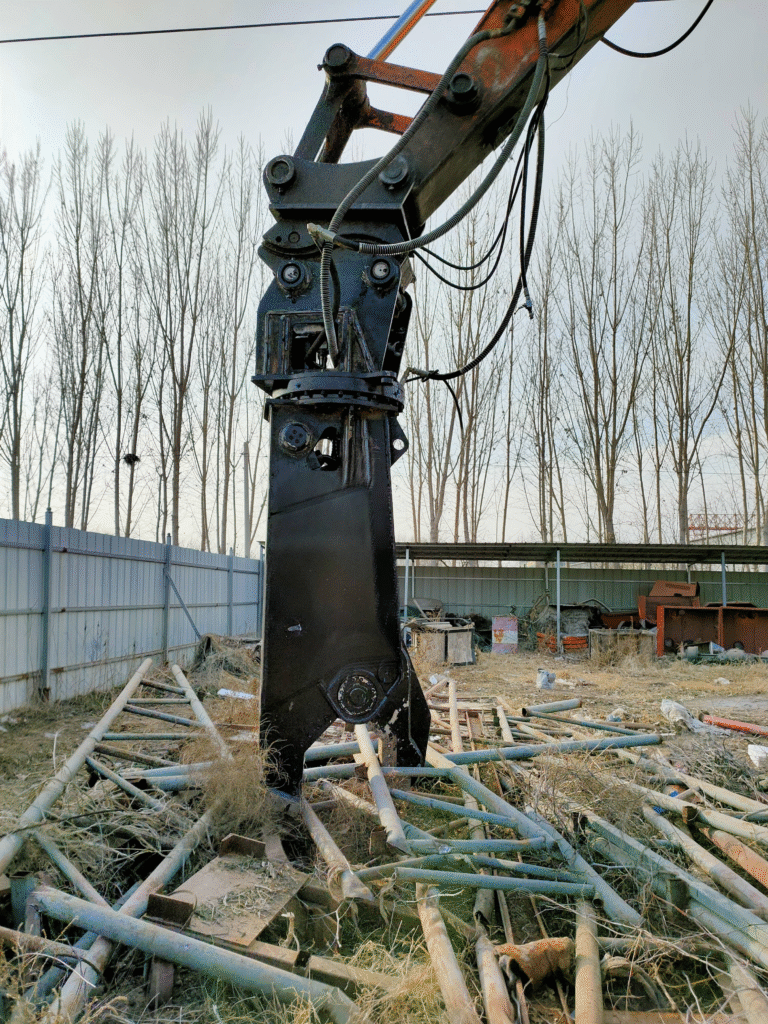

1. SH Series (Single-Cylinder Hydraulic Shears)

Features:

Single-cylinder design, compact construction, and powerful power.

Applications:

Designed specifically for shearing rebar, scrap steel, and metal structures, suitable for use in scrap recycling stations and steel structure demolition.

Advantages:

High shearing force, flexible operation, and easy maintenance.

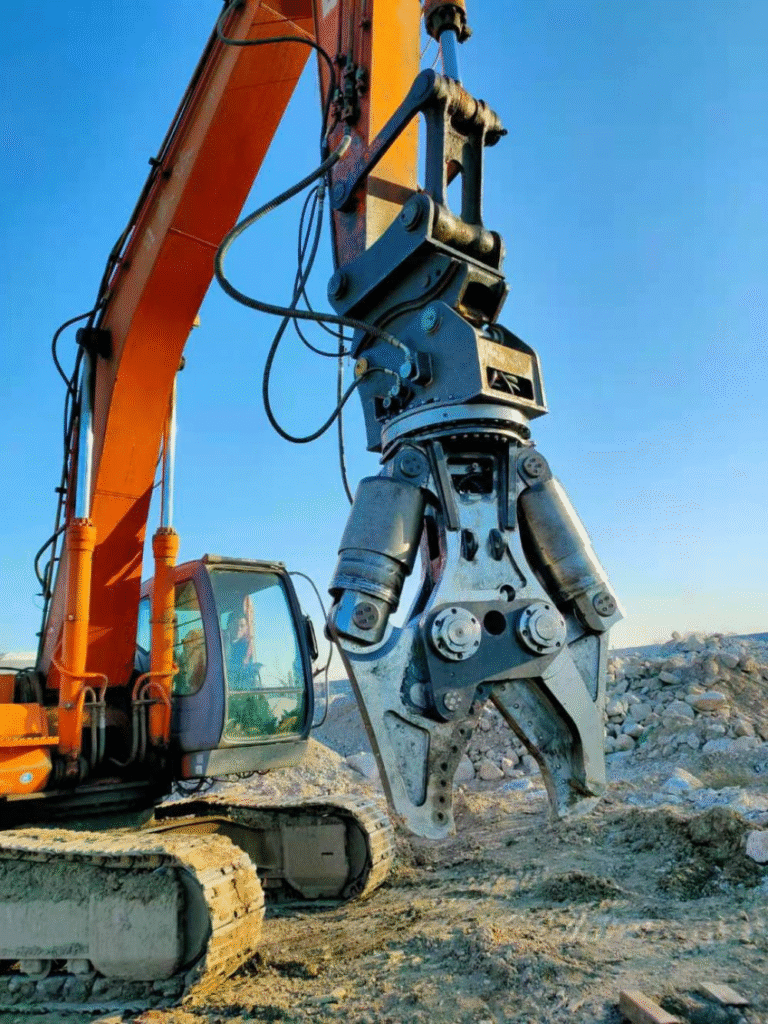

2. RP Series (Rotary Secondary Pulverizer)

Features:

Equipped with a 360° rotation function, the shear position can be adjusted at multiple angles.

Applications:

Suitable for secondary crushing of concrete and rebar mixtures, such as for fine processing after demolition of floor slabs, beams, and columns.

Advantages:

The rotating design improves work efficiency and precisely crushes the rebar and concrete mixture.

3. MCP Series (Non-Rotary Secondary Pulverizer)

Features:

Fixed design, stable structure, and strong impact resistance.

Application:

For secondary crushing of concrete and rebar mixtures, particularly suitable for high-intensity crushing operations.

Advantages:

High durability, suitable for long-term continuous operation, and low maintenance costs.

4. CR Series (Primary Crushing Shear)

Features:

Large opening design, strong cutting force, suitable for coarse crushing operations.

Application:

Used for primary demolition of structures such as buildings and bridges, and for quickly shearing house frames and steel structures.

Advantages:

Highly efficient crushing, shortening overall demolition time.

DS Series (Dual Cylinder Hydraulic Shear)

Features:

Dual cylinder drive, stronger cutting force and greater stability.

Application:

Designed for efficient shearing of rebar, thick steel plates, and metal scrap, suitable for large scrap processing plants.

Advantages:

High operating efficiency, suitable for high-intensity continuous operation, and excellent durability.

How do I choose the right hydraulic shear for my needs?

1. Excavator model

2. Is it compatible with the long boom and arm?

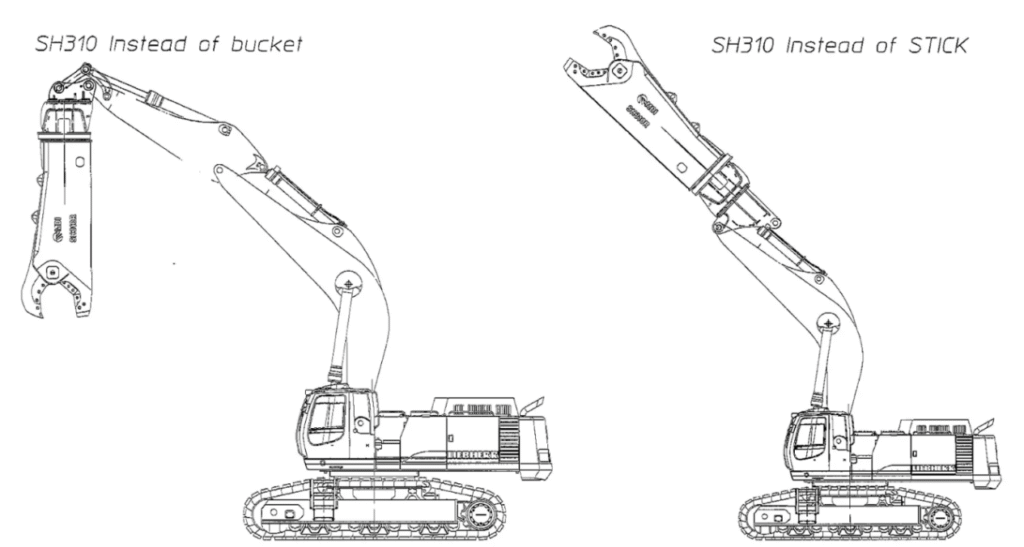

3. Is it mounted on a boom or a stick?

4. Project details

Precautions for the use of hydraulic shears

CAUTION: Do not use the shear as a fulcrum for moving the operating machine.

DANGER: It is forbidden to use the shear for cutting tempered steel or fused parts. Chips of material or splinters could be projected at great distances, causing serious damage to people or things.

DANGER: Do not strike those parts of the machine in tempered steel, except with non-ferrous hammers. Splinters could fly off and injure people nearby.

CAUTION: Position the shear in such a way as to prevent the pieces that have been cut from being projected in the direction of the cabin.

WARNING: Before cutting thin materials, make sure that the shear blades are in good condition and that the play between the blades is correct; otherwise the material could become caught between the blades.