Complete Guide to Brush Mowers: From Understanding to Selection

In scenarios like large-scale barren mountain vegetation restoration, orchard weed cleaning, municipal greening maintenance, or shrub trimming in agricultural and forestry operations, have you ever faced such troubles? Traditional manual weeding not only requires a huge investment in labor costs, but when dealing with weeds half a meter tall or shrubs several centimeters in diameter, the efficiency of sickles and hoes is frustratingly low. What’s more, it is often accompanied by safety risks such as cuts and bumps. Especially when the operation scope expands to dozens or even hundreds of acres, “time-consuming, labor-intensive, and unsafe” has almost become an insurmountable bottleneck for manual weeding.

The Brush Mower we’re going to talk about today is precisely a professional equipment developed to address these pain points. With its high-efficiency cutting capability and flexible adaptability to different scenarios, it has gradually replaced traditional tools and become an “efficiency champion” in various vegetation trimming operations.

However, faced with the wide variety of Brush Mowers on the market, many people inevitably have questions: What exactly is it? What types are available? Which one should be used for different scenarios? And how to choose the most suitable one for yourself?

Don’t worry. This blog will take you to fully understand Brush Mowers from basics to advanced knowledge. We will first clarify its core definition, then break down its various types, deeply analyze its working principle and applicable scenarios, and finally provide practical purchasing advice. Whether you are an agricultural and forestry practitioner, a greening project manager, or a user with large-area weeding needs, after reading this article, you will have a clear understanding of Brush Mowers and easily avoid selection mistakes.

What is Brush Mower?

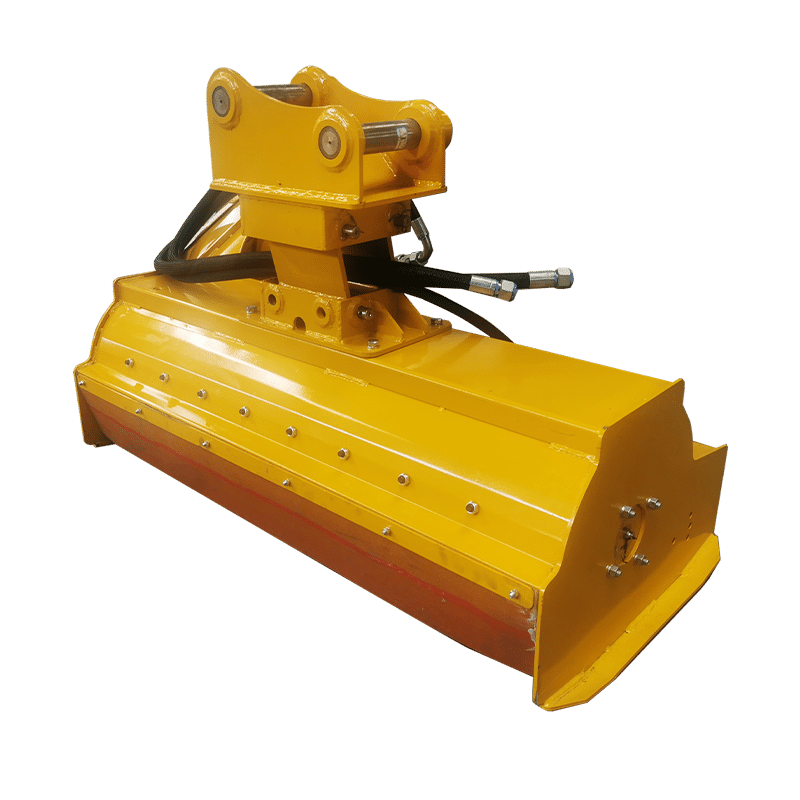

The Excavator-mounted Brush Mower is a professional weeding device mounted on the front of an excavator, mainly used for trimming vegetation in large-scale barren mountain areas. Its core working principle is as follows: a dedicated cutting blade is installed on the output shaft of the hydraulic motor, and the blade completes vegetation cutting through the high-speed rotational power provided by the hydraulic motor.

The core advantages of this equipment lie in significantly reducing labor input and time costs for weeding operations, while fundamentally lowering the safety risks of manual operations and ensuring the safety of construction personnel. Recommended working conditions: Suitable for trimming weeds or shrubs with a diameter of approximately 5 cm.

Key Selling Points

Core Advantages

Our brush mowers stand out with versatility to handle complex tasks, durability through optimized

protection designs, customizability for diverse needs, operational stability via precision testing, and premium performance backed by top-tier components like NSK bearings—delivering efficiency, longevity, and peace of mind in every operation.

What types of Brush Mower are there?

The type of blade on your brush mower makes all the difference in performance. Here’s the quick breakdown between Y-blades and Drum knives:

- Y-blades: Designed for weeds. Their sharp, Y-shaped edges slice through soft, thin vegetation (up to 2cm in diameter) quickly and cleanly. Perfect for grass, light weeds, and tender growth.

- Drum knives: Built for shrubs. With heavy, hammer-like blades on a rotating drum, they crush and tear through woodier, thicker growth (2-5cm in diameter). Ideal for tough bushes and woody stems.

In short: Y-blades for soft weeds, drum knives for harder shrubs. Match the blade to what you’re cutting, and you’ll get the best results.

How does the Brush Mower work and in which scenarios can it be used?

Working Principle

A brush mower works by using a hydraulic motor to drive blades (like Y-blades or drum knives) at high speeds. The rotating blades cut through or shred vegetation—whether soft weeds or woody shrubs—using their sharp edges or impact force, efficiently trimming the targeted growth.

Application Scenarios

Brush mowers excel in diverse outdoor spaces where vegetation control is needed. They’re widely used in:

- Barren mountain slopes or rough terrains, taming overgrown shrubs and weeds.

- Orchards and farmlands, clearing grass and light brush between rows.

- Roadside verges and railway edges, trimming unruly plants to maintain safety.

- Forest edges or abandoned lands, managing thickets and woody growth up to 5cm in diameter.

- Municipal green spaces, keeping parks, embankments, and green belts neat.

Essentially, anywhere with dense weeds, bushy patches, or woody stems that need efficient, heavy-duty trimming.

How to choose the best suitable Brush Mower?

Selecting the right Brush Mower depends on project needs and operational conditions. Key factors to consider include:

1. The model/weight of excavator? Select a Brush Mower suitable for you based on the model, tonnage and oil flow range of your excavator.

2. The work width what you want? Work width is selected based on the width of work you need.

3. What type of specific trimming conditions are we referring to? If there are many shrubs in the pruning area, a drum knife is recommended. If there are more weeds, a Y-shaped knife is recommended. If the diameter of the trimmed weeds is larger than 5 cm, it is not recommended to use this product.

| Model | Unit | RBM-06 | RBM-08 | RBM-10 | RBM-12 | RBM-14 | RBM-16 | RBM-18 | RBM-20 |

|---|---|---|---|---|---|---|---|---|---|

| Carrier Weight | T | ≦3 | 3-5 | 5-6 | 6-10 | 10-18 | 20 | ≥20 | ≥20 |

| Working Pressure | Bar | 150-300 | 150-300 | 150-300 | 150-300 | 150-300 | 150-300 | 150-300 | 150-300 |

| Working Oil Flow | L/min | 15-35 | 30-55 | 40-60 | 30-70 | 70-150 | 120-200 | 120-200 | 120-200 |

| Weight | Kg | 120 | 132 | 230 | 300 | 420 | 500 | 555 | 600 |

| Motor Speed | Rpm/min | 2500-3000 | 2500-3000 | 2500-3000 | 2500-3000 | 2500-3000 | 2500-3000 | 2500-3000 | 2500-3000 |

| Quantity of Blades | Pcs | 20 | 28 | 36 | 44 | 48 | 56 | 64 | 72 |

| Work Width | mm | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 |

| Length | mm | 820 | 1040 | 1260 | 1460 | 1720 | 1920 | 2160 | 2360 |

| Width | mm | 470 | 530 | 630 | 630 | 650 | 650 | 620 | 650 |

| Height | mm | 620 | 650 | 820 | 900 | 980 | 1030 | 1100 | 1100 |

Conclusion: Get the Most Out of Your Brush Mower

If you’ve been stuck with slow, tiring manual weeding or shrub trimming, a brush mower is your solution—it cuts through weeds and woody growth under 5cm efficiently, saving you time, labor, and the risk of injuries.

To make it work best for you: First, match the blade to your task—Y-blades handle soft weeds cleanly, while drum knives tackle tougher shrubs. Second, don’t overlook the small but impactful features: reversible rotation for tricky spots, debris-resistant bearing covers to avoid jams, pre-testing for stable operation, and quality NSK bearings for long-lasting use. These details keep your machine running smoothly and reduce hassle.

At the end of the day, the right brush mower isn’t just a tool—it turns tedious outdoor trimming into a faster, safer job. Pick one that fits what you’re cutting and where, and you’ll wonder how you managed without it.