What is A earth auger & How Does It Work?

In current construction industry, adapting to advancements in equipment and technology is critical for maintaining competitiveness. As projects grow more complex and timelines tighten, the ability to leverage tools that enhance productivity and precision becomes increasingly vital.

Among these innovations, hydraulic systems have emerged as a cornerstone of modern construction equipment—offering superior power density, precise control, and operational efficiency that traditional mechanical or electric tools struggle to match.

This technological shift has driven a noticeable trend: an increasing number of contracting firms are integrating hydraulic excavation tools into their fleets, recognizing their role in enhancing project scalability and cost-effectiveness. Yet for all their growing prevalence, one key piece of hydraulic equipment remains underexplained: the hydraulic auger. What sets it apart from conventional drilling tools? How does its hydraulic mechanism translate to on-site performance? In this article, we’ll dissect its operational principles, highlight its core advantages, and map out its practical value across diverse construction applications.

What is Hydraulic earth auger?

A hydraulic earth auger is a power-driven drilling tool designed to bore holes in soil, earth, and related materials, operating via hydraulic systems that convert fluid pressure into rotational kinetic energy. Unlike manual or electric augers, it delivers far greater power and speed, making it a versatile tool in construction, agriculture, landscaping, and infrastructure projects. Some models can reach rotation speeds of up to 19 revolutions per minute, with wide applications in excavations, shaft sinking, and roadwork.

Core Advantages

Hydraulic earth augers offer distinct advantages over standard drills:

- Higher power-to-weight ratio for efficient operation

- Faster penetration into diverse materials (soft/hard soil, concrete, asphalt)

- Enhanced drilling speed—up to 2.44 meters per minute (varies by diameter)

- Steady torque from hydraulic pressure, with performance unaffected by bentonite clay (unlike air or electric rigs)

- Larger drill pipes (wider-diameter shafts) enabling deeper holes, ideal for tasks like shaft sinking

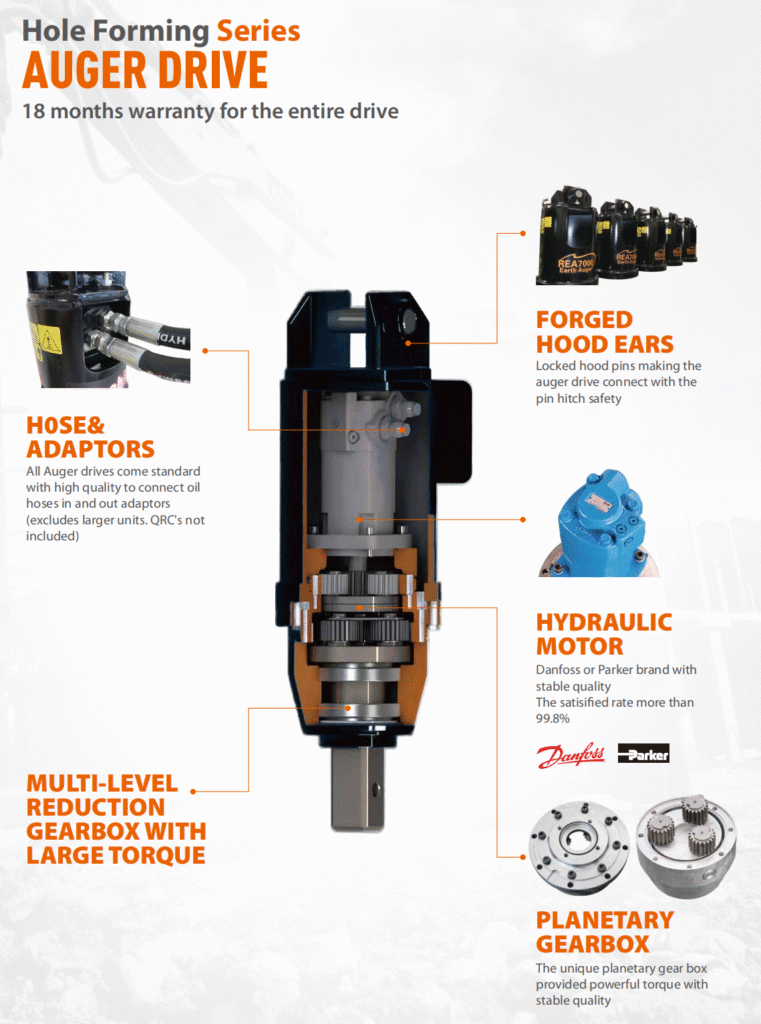

Our Product Advantages

Beyond these universal strengths, our hydraulic earth augers stand out with exclusive features:

Premium Motor & Quality: Equipped with 100% DANFOSS motors, backed by an 18-month warranty, with a 99.98% production pass rate for consistent reliability.

Stable Torque & Longevity: Integrated reduction gearboxes ensure steady torque output and extend service life significantly.

Durable Construction: Precision welding prevents cracking under heavy use; shot blasting technology eliminates internal stress, boosting structural strength.

Easy Maintenance: All in-house manufactured spare parts have unique serial numbers traceable to their production date, simplifying replacements.

Key Features

- Hydraulic-driven design: Integrates with hydraulic power units (HPUs) connected to machinery like excavators or skid steer loaders, etc.

- Robust build: Engineered to withstand rugged environments and heavy-duty use.

- Versatile compatibility: Adaptable to various project scales, from small residential tasks to large construction sites.

What types of Hydraulic earth auger are there?

Our hydraulic earth augers are categorized by application scenarios and machinery compatibility to meet diverse project needs:

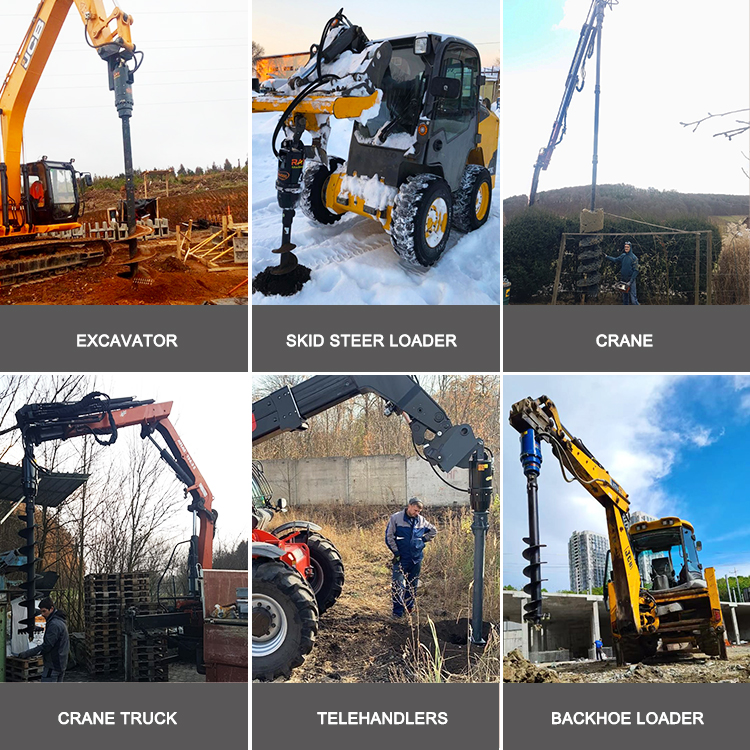

- Excavator-Mounted Hydraulic Earth Augers: Designed for excavators (1–50 tons), ideal for large-scale construction—such as foundation drilling, shaft sinking, and heavy-duty earthwork. Available with drill diameters of 10–240 cm, suitable for deep, wide holes.

- Tractor-Mounted Hydraulic Earth Augers: Compatible with tractors, focusing on agricultural and landscaping tasks (tree planting, fence post installation). Compact yet powerful.

- Skid Steer-Mounted Hydraulic Earth Augers: Lightweight and flexible, attached to skid steers for residential projects (drainage installation, small-scale infrastructure). Features quick-connect mechanisms for easy task switching.

- In addition, it can also be used for backhoe loaders, cranes, trucks, telehandlers, etc.

How does the Hydraulic earth auger work and in which scenarios can it be used?

Working Principle

A hydraulic earth auger converts hydraulic pressure into kinetic energy via its drill stem. The hydraulic oil causes the motor to drive the gear to rotate, the gear drives the output shaft to rotate, and the output shaft drives the drill pipe to rotate to work.

Application Scenarios

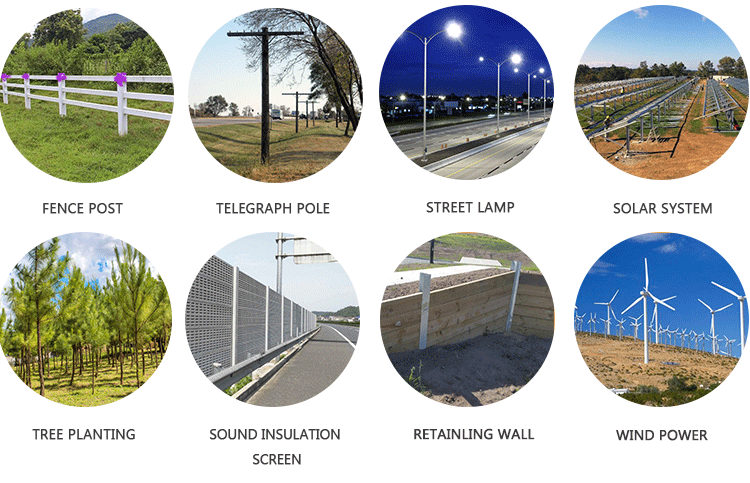

Hydraulic earth augers are versatile across residential, commercial, and industrial projects:

- Fencing: Efficiently bore holes for fence posts, electric poles, or gate installations.

- Foundation work: Drill deep holes for building foundations, easily filled with concrete or building materials.

- Drainage & well drilling: Install drainage systems (driveways, sidewalks), septic tanks, or dig water wells.

- Gardening & landscaping: Quickly drill planting holes for trees and plants, simplifying landscaping tasks.

- Pole installation: Bore deep foundations for utility poles, street signs, or elevated structures.

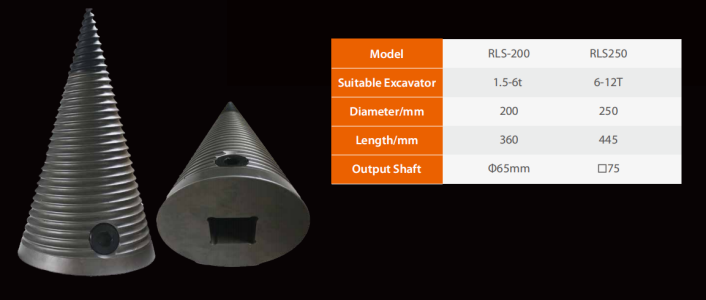

Hydraulic auger equipped with a Log splitter device:

Log splitter is a specialized hydraulic accessory installed on auger drive, specifically designed for efficient splitting of wood. It utilizes the hydraulic power system of the drilling machine and, through mechanical structures, converts hydraulic energy into directional splitting force, enabling rapid disassembly of tree trunks, thick logs, and hard woods. It is a mechanized tool that replaces manual splitting of wood and chainsaw cutting, and is widely used in forestry logging, engineering clearance, and wood processing scenarios.

Hydraulic auger equipped with a stump planer device:

Stump planer is a special hydraulic attachment mounted on auger drive. It is equipped with a hydraulic power system that converts hydraulic energy into directional planing force, and uses a high-speed rotating or reciprocating planer assembly to trim, shape or cut the wood surface (such as planing the surface of a tree trunk, processing a wooden block, cleaning bark, etc.). It is a mechanized tool that replaces manual planing or small woodworking machinery, and is suitable for scenes such as wood processing, garden modeling, and engineering wood sculptures.

Hydraulic auger equipped with a mixer bowl device:

The mixer bowl mounted on auger drive uses its power to drive the mixing device to achieve uniform mixing of cement, mortar and other building materials. It is suitable for field infrastructure, small-scale projects and other scenarios, replacing traditional mixing equipment.

How to choose a best suitable Hydraulic earth auger?

Selecting the right hydraulic earth auger depends on project needs and operational conditions. Key factors to consider include:

1. The model / weight of excavator? Select a Hydraulic earth auger suitable for you based on the model, tonnage and oil flow range of your excavator.

| Model | Oil Folw | Max Torque | Pressure | Rotary Speed | Carrier | Oil Hose | Drill Dia. | |||||

| gal./min | I/min | Lbf·Ft | N·M | Psi | Bar | Rpm | T | Lbs/Pounds | Inch | mm | Inches | |

| REA2000 | 5-12 | 23-53 | 1386 | 1871 | 3000 | 205 | 40-92 | 1-2.5 | 2205-5512 | 1/2 | 100-400 | 4-16 |

| REA2500 | 6-14 | 30-61 | 1802 | 2432 | 3000 | 205 | 40-82 | 1.5-3 | 3307-6614 | 1/2 | 100-500 | 4-20 |

| REA3000 | 6-14 | 30-61 | 2132 | 2877 | 3500 | 240 | 40-81 | 2-3.5 | 4409-7716 | 1/2 | 100-600 | 4-23 |

| REA3500 | 6-15 | 30-68 | 2678 | 3614 | 3500 | 240 | 32-72 | 2.5-4.5 | 5512-9921 | 1/2 | 100-750 | 4-29 |

| REA4500 | 8-17 | 38-76 | 3334 | 4499 | 3500 | 240 | 32-64 | 3-5 | 6614-11023 | 1/2 | 100-900 | 4-35 |

| REA5000 | 8-17 | 38-76 | 3747 | 5056 | 3500 | 240 | 29-58 | 4.5-7 | 9921-15432 | 1/2 | 150-600 | 6-23 |

| REA5500 | 10-18 | 45-83 | 4379 | 5910 | 3500 | 240 | 28-50 | 5-7 | 11023-15432 | 1/2 | 150-750 | 6-29 |

| REA6000 | 10-24 | 45-106 | 4557 | 6150 | 3500 | 240 | 34-80 | 6-8 | 13228-17637 | 3/4 | 150-900 | 6-35 |

| REA7000 | 14-27 | 61-121 | 5136 | 6931 | 3500 | 240 | 37-72 | 7-10 | 15432-22046 | 3/4 | 150-900 | 6-35 |

| REA8000 | 14-30 | 61-136 | 6041 | 8152 | 3500 | 240 | 29-64 | 8-12 | 17637-26455 | 3/4 | 150-900 | 6-35 |

| REA10000 | 15-30 | 70-136 | 7987 | 10778 | 3500 | 240 | 26-45 | 10-13 | 22046-28660 | 3/4 | 150-900 | 6-35 |

| REA12000 | 18-31 | 80-140 | 8874 | 11976 | 3500 | 240 | 22-43 | 13-17 | 28660-37479 | 1 | 150-900 | 6-35 |

| REA15000 | 18-34 | 80-151 | 11149 | 15046 | 3500 | 240 | 20-39 | 13-17 | 28660-37479 | 1 | 150-1200 | 6-47 |

| REA20000 | 18-38 | 80-170 | 14494 | 19560 | 3500 | 240 | 17-34 | 13-20 | 28660-44092 | 1 | 150-1200 | 6-47 |

| REA25000 | 18-38 | 80-170 | 18488 | 24949 | 3500 | 240 | 16-30 | 15-23 | 33069-50706 | 1 | 150-1200 | 6-47 |

| REA35000 | 18-38 | 80-170 | 26132 | 35265 | 4500 | 310 | 9-24 | 20-45 | 44092-99208 | 1 | 300-1500 | 12-59 |

| REA42000 | 18-38 | 80-170 | 31358 | 42318 | 4500 | 310 | 9-20 | 20-45 | 44092-99208 | 1 | 300-1500 | 12-59 |

| REA50000 | 22-62 | 100-280 | 35116 | 47389 | 4650 | 320 | 11-30 | 20-50 | 44092-110231 | 1 1/4 | 300-1500 | 12-59 |

| REA65000 | 22-62 | 100-280 | 46089 | 62197 | 5100 | 350 | 9-25 | 20-50 | 44092-110231 | 1 1/4 | 300-1500 | 12-59 |

| REA100000 | 22-62 | 100-280 | 76702 | 103509 | 5100 | 350 | 5-13 | 20-50 | 44092-110231 | 1 1/2 | 300-1800 | 12-70 |

2. The diameter & depth of hole? Based on the specific depth and diameter of the hole you need to excavate, choose the appropriate diameter and length of the drill pipe.

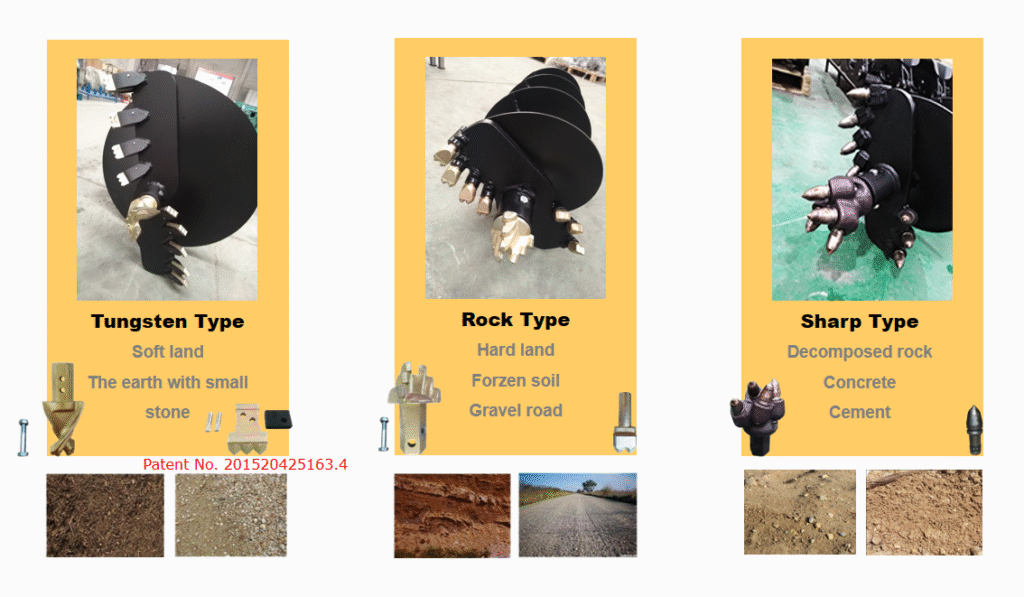

3. The type of soil? Soft or hard? Choose the appropriate auger bit based on the hardness of the soil you need to drill. We have tungsten auger bits, rock auger bits, and sharp auger bits, which are suitable for various types of soil.

Conclusion

In the vast expanse of engineering, the earth auger is not merely cold steel – it is the bridge connecting demands with solutions, and the versatile “multi-tool” that simplifies complex operations. From cutting wood, planing to mixing cement, the attachments mounted on the drilling rig embody an ultimate pursuit of efficiency: one less transfer means greater precision; one less piece of equipment means greater flexibility.

It has witnessed the formation of foundation piles in the mountains, and also participated in the renovation of the village road at the entrance. It can split hard wood and mix uniform mortar. Essentially, the evolution history of the drilling machine is also the continuous practice by engineers of the concept of “adapting to local conditions” – using more suitable tools to deal with more complex scenarios.

Perhaps in the future, it will be more intelligent and more lightweight, but what remains unchanged is that spirit of “rooting wherever needed”.

See you next time. May your auger drill always be full of power, and all the projects under your supervision be completed on time and successfully.