What is a Vibro ripper? How does it work?

Vibro ripper is a physical crushing device that integrates mechanical hydraulics and digital monitoring. Under the action of the vibrator, the teeth of the vibrating ripper impact the object to be crushed (crushing target), thereby crushing the object to be crushed.

The hydraulic system of the excavator provides power for the Vibro ripper. The hydraulic oil enters the vibration box, drives the hydraulic motor to rotate the driving shaft, and the driving shaft drives the driven shaft to rotate together through the gear transmission. The eccentric wheel installed on the shaft rotates to generate centrifugal force, so that the shaft produces radial forced vibration, forming a high-frequency exciting force.

The vibration box transmits the high-frequency vibration to the vibrating hook and bucket teeth, so that the bucket teeth act on the soil, rocks and other targets in a high-frequency impact manner to break or loosen them.

What are the advantages of a Vibro ripper?

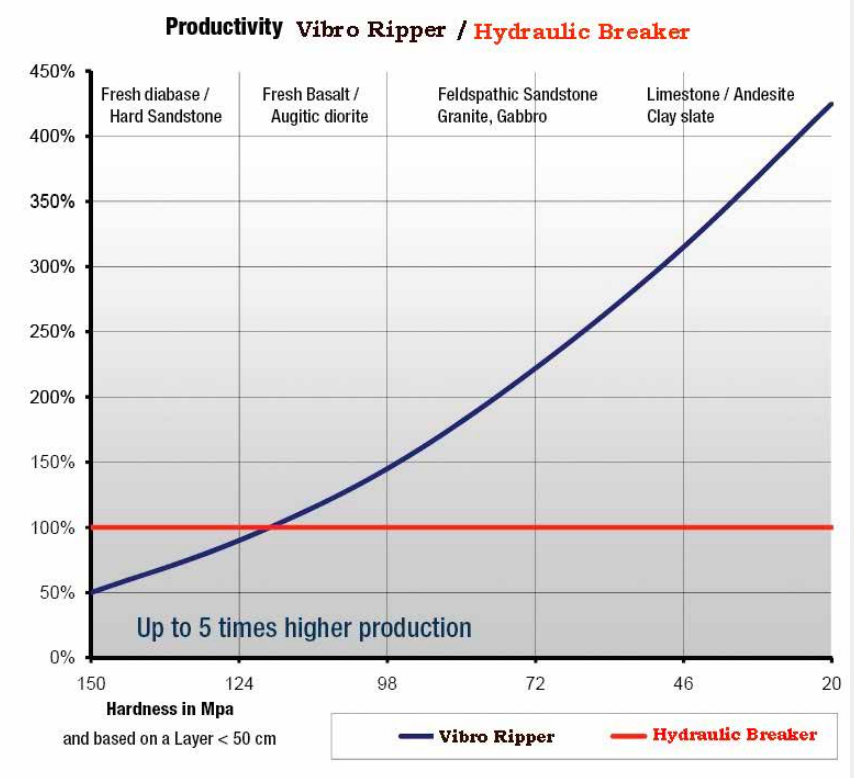

High efficiency crushing: output is 2 to 5 times higher than hydraulic hammer

Energy saving and environmental protection: Compared with traditional equipment such as breakers, it has less noise pollution to the surrounding environment, low energy loss and high operating efficiency.

Wide range of applications: Its vibration structure usually adopts a fully sealed device, which can adapt to underwater operations and various harsh working conditions, such as the crushing of red sandstone, quartz sand, kaolinite, basalt, slate, gypsum, shale, asphalt, concrete, limestone, weathered stone, phosphate rock, open-pit coal mines, frozen soil, ice layers, etc.

Low maintenance cost: Due to the use of advanced design and manufacturing technology, the structure of the high-frequency tiller is relatively simple, the service life of the parts is long, the maintenance work is relatively easy, and the maintenance cost is low. For example, the bearing heat sink can effectively reduce the bearing temperature and extend the bearing service life. The air filter can prevent dust from entering the vibration box, ensure the cleanliness of the lubricating oil, and reduce component wear.

What is the productivity of a Vibro ripper?

RAY Vibro ripper outperforms hydraulic breakers in 80% of applications. In up to 70% of applications, it can deliver 2 to 5 times more output.

What are the application areas of a Vibro ripper?

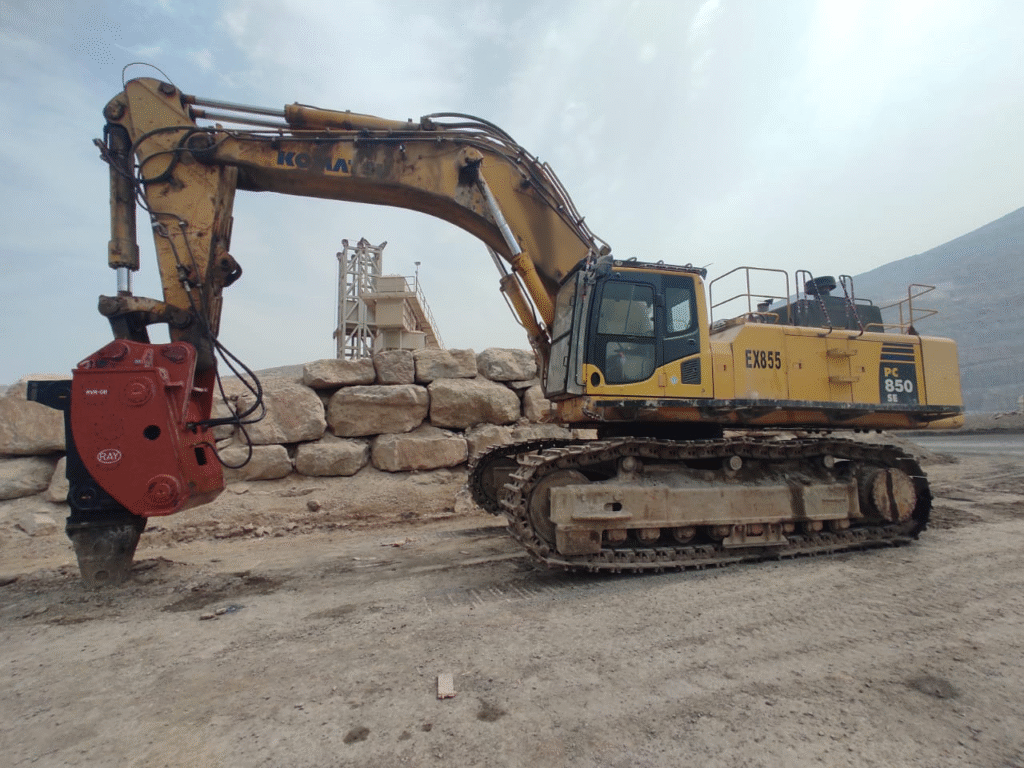

Mining: In mining, it can be used to crush and turn over soft rocks, weathered rocks, cracked rock formations, etc., to facilitate subsequent excavation and loading operations and improve mining efficiency.

Road construction: It can be used to excavate asphalt pavement, break up hard soil and frozen soil, etc., and provide preliminary site preparation for road construction, widening, repair and other projects.

Building foundation construction: In building foundation construction, it can be used to crush concrete, rocks, etc., to create conditions for excavation and treatment of the foundation, and to facilitate subsequent infrastructure construction work.

Water conservancy projects: In the construction of water conservancy projects, it can be used to break riverbed rocks, frozen soil, etc., and provide basic construction support for the construction of water conservancy facilities such as dams and canals.

How to select a Vibro ripper?

You can use the table below to preliminarily determine the appropriate model according to the tonnage of your excavator.

Of course, in order to better confirm the matching model, you need to confirm the excavator model, excavator age, project conditions, stone hardness, etc.

| Parameter | Unit | RVR-30 | RVR-40 | RVR-50 | RVR-60 |

|---|---|---|---|---|---|

| Power | KW | 75 | 75 | 85 | 102 |

| Motor | CC | 90 | 90 | 110 | 125 |

| Impact force | KN | 295 | 315 | 385 | 450 |

| Length | mm | 2780 | 2780 | 3235 | 3235 |

| Width | mm | 960 | 960 | 1110 | 1110 |

| Height | mm | 1400 | 1400 | 1565 | 1565 |

| Working flow | L/min | 120-170 | 145-195 | 155-210 | 175-250 |

| Working pressure | MPa | 26-31 | 26-31 | 26-31 | 26-31 |

| Weight | kg | 1000 | 1200 | 5000 | 5500 |

Installation of a Vibro ripper.

1.Read the instructions: Please read the instructions provided carefully before operating your Vibro Ripper.

2.Connect excavator: First step is install excavator’s connecting shaft.

3.Connect oil pipe: Use the supplied main inlet and return hydraulic hoses to connect the main oil inlet and main return port to the oil inlet and return hard pipes of the excavator’s backup pipeline respectively as shown in the right view; the hydraulic high-speed motor drain port is supplied with the supplied The drain pipe is directly connected to the hydraulic oil tank of the excavator, and must not be connected in parallel or in parallel with any oil pipe or valve group.

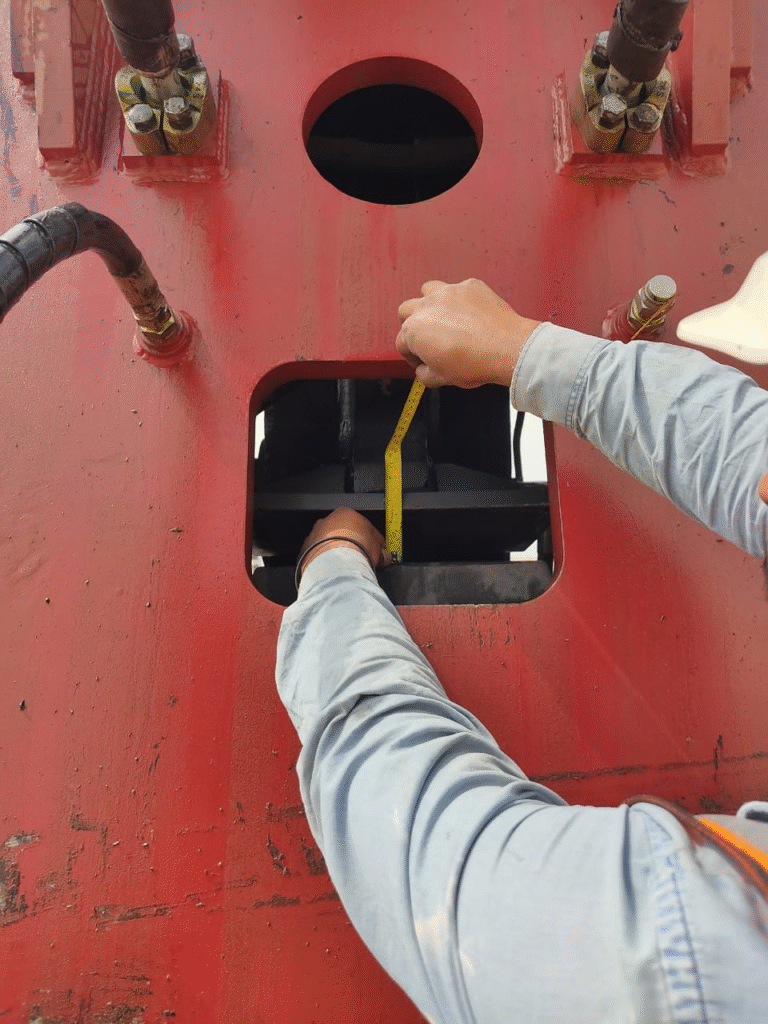

4.Check the movement gearbox gear oil level: After the Vibro Ripper is connected to the excavator, stand vertically on the ground and visually check the gear oil level of the machine core. When the gear oil level is higher than the oil level, it is sufficient. When the oil level is lower than the oil level, it must be added to the level above the oil level before use (gear oil specification: RAY special heavy-duty gear oil AP-320, or gear oil of equivalent viscosity).

5.Check rubber air spring air pressure: When the Vibro Ripper is in standby mode, the air spring is flushed with nitrogen or air to a pressure of 4~9kg (nitrogen is recommended).

Because the excavator is old and new and the brand is different, the lower pressure of the boom is also different, so the air spring pressure can be adjusted according to the following method: Place the vibro ripper perpendicular to the ground, and press the excavator boom vertically down to the ground until it reaches the front of the excavator. It can be used only when the crawler track is 20cm away from the ground and the Vibro Ripper core is 50mm away from the stroke limit rubber.