What is A crusher bucket & How Does It Work?

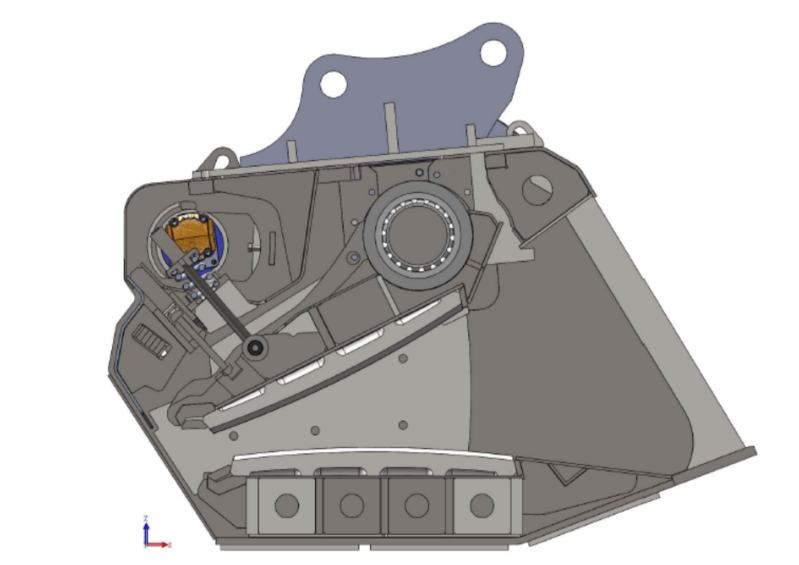

A bucket crusher or crusher bucket is a type of jaw crusher. It’s an attached tool for excavators for built-in crushing construction waste and demolition materials. It has the design of a shovel, which is open at the rear for releasing the shredded material.

How Does crusher bucket work?

The upper end of the movable jaw of the crusher buckets is directly suspended on the eccentric shaft, which is directly driven by the eccentricity of the shaft, and the lower end of the movable jaw of the jaw crusher is connected with the shaft plate and spring.

When the crusher buckets is started, the eccentric shaft rotation will be followed by rotation, at this time, the trajectory of each point on the moving jaw of the equipment from the suspension point of the circumference of the line (radius equal to the eccentric distance), and then gradually downward movement into an ellipse!

How to choose?

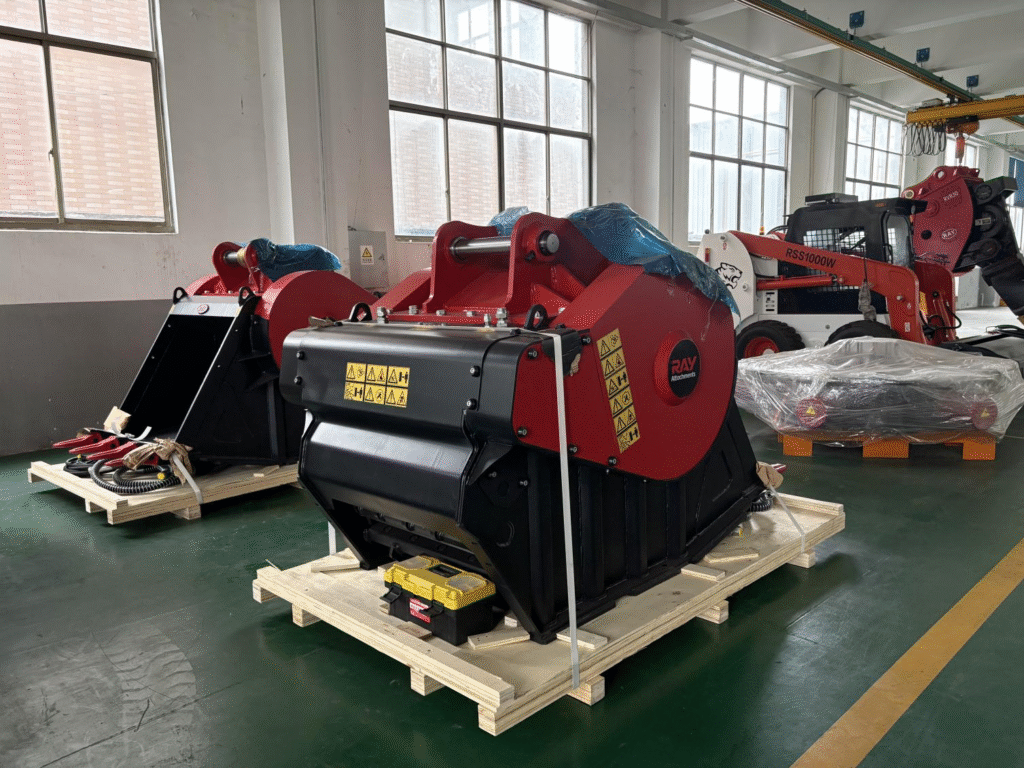

Usually we will recommend according to the model of the excavator owned by the customer, but also with the materials to be crushed, the project situation and budget. We now have two models RMB80 and RMB120, they can be used for 20-40T excavators. At the same time, we are actively developing new models to meet the needs of different customers.

| Model | unit | RMB80 | RMB120 |

|---|---|---|---|

| Excavator | ton | 20-30 | 33-40 |

| Weight | kgs | 3500 | 5500 |

| Bucket Capacity | cbm | 0.8 | 1.3 |

| Size | mm | 2080*1425*1600 | 2500*1650*1800 |

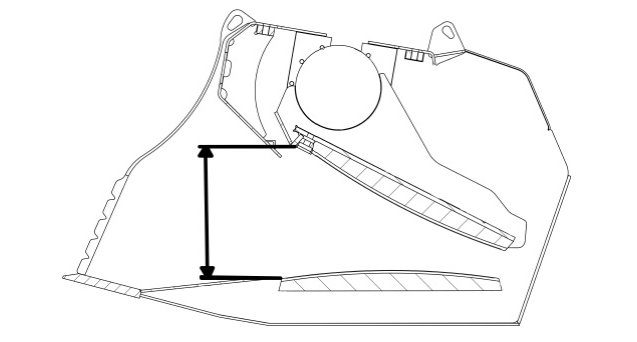

| Bucket Opening Size | W*H(mm) | 910*510 | 1350*540 |

| Hydraulic Motor | oil pressure(bar) | ≤230 | ≤230 |

| oil flow(L/min) | 150-200 | 190-230 | |

| Output (T/H) | 20mm | 12 | 20 |

| 30mm | 15 | 25 | |

| 40mm | 18 | 28 | |

| 50mm | 22 | 30 | |

| 60mm | 25 | 33 | |

| 70mm | 28 | 35 | |

| 80mm | 30 | 40 | |

| 90mm | 33 | 43 | |

| 100mm | 35 | 47 | |

| 110mm | / | 50 | |

| 120mm | / | 55 | |

| 130mm | / | 58 |

Crusher Bucket

How to operate and maintain?

How to operate the crusher bucket?

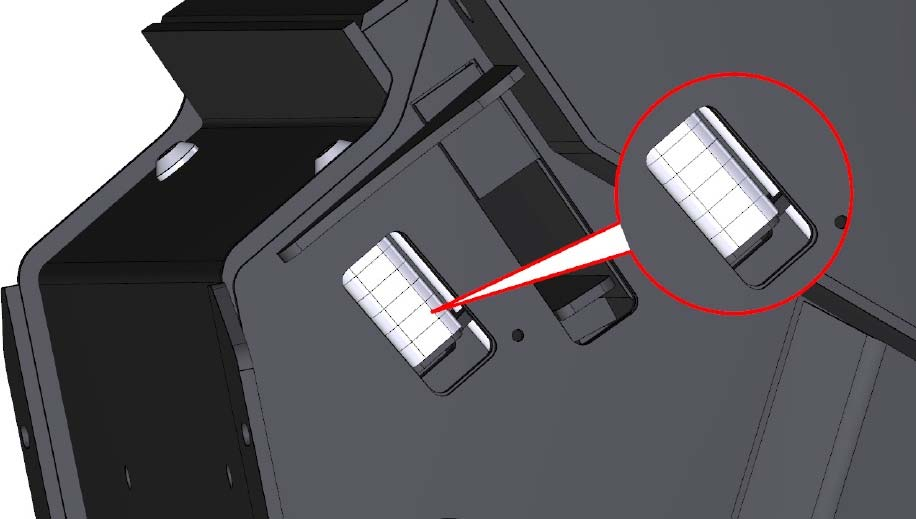

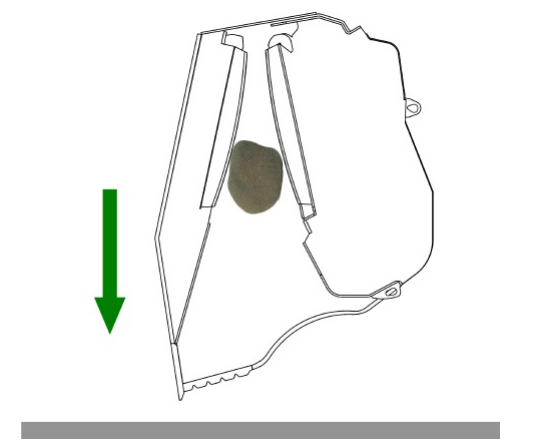

1. Mount the gravel bucket on the excavator as shown below and connect the hydraulic lines.

2. Start the crusher bucket and let the machine motor run for a few minutes first. (During the winter season when temperatures are low, keep the motor switched on for about 10 minutes and wait until the temperature of the hydraulic fluid has risen by about 40°C before using the crusher buckets.)

3. Pause the crusher buckets rotation and start loading the material to be crushed. Re-activate the throttle again in a slow and gradual manner, allowing the buckets to increase its speed to the specified maximum speed.

4. Slowly adjust the position of the crushing hopper outlet so that the outlet is facing downwards, which is conducive to the falling and discharging of materials.

5. Until the material inside the crusher bucket has been crushed, repeat the above operation.

How to adjust the size of the outlet?

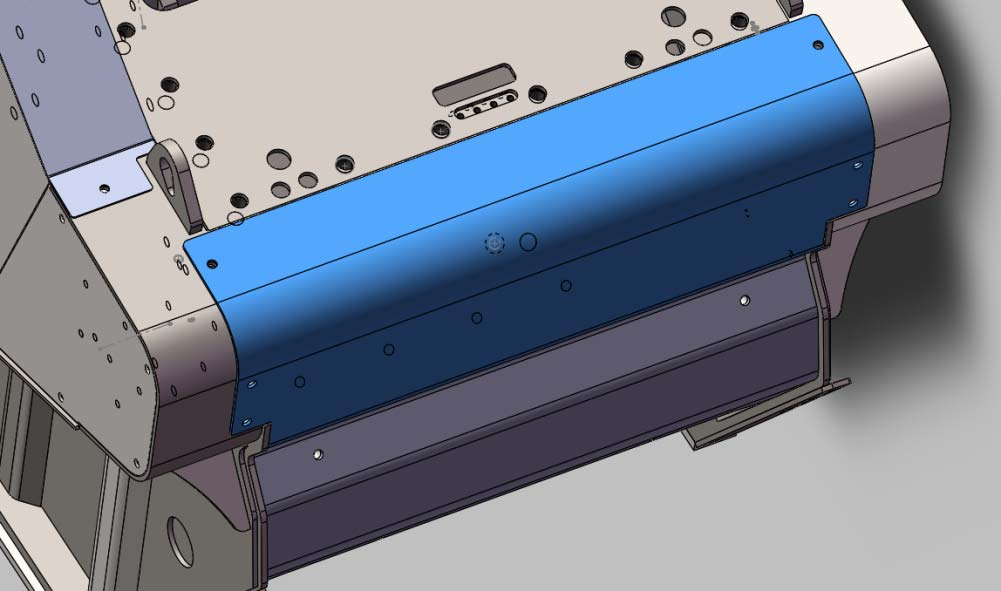

1. Remove rear hatch cover.

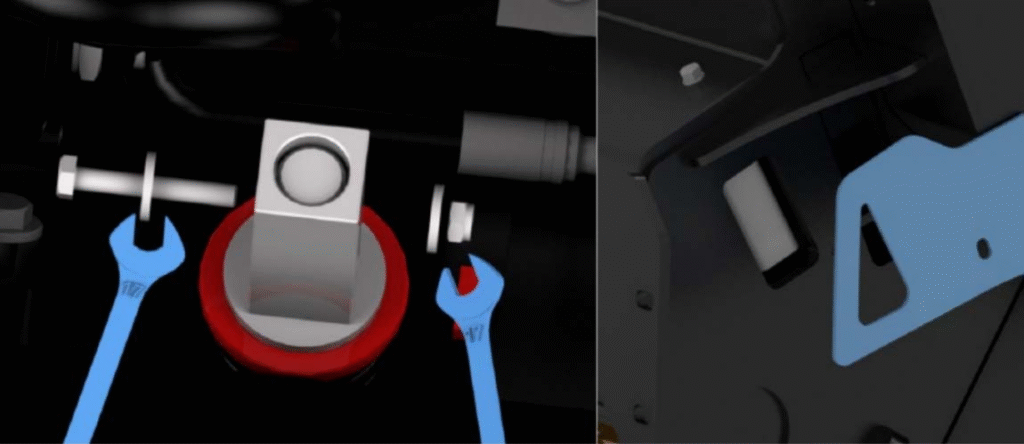

2. Remove the safety screw of square nuts.

3. Turning the square nut lowers the moving jaws.

4. Remove the shims from the storage slot and place them into the adjustment bin section of the elbow plate. Inserting the shim reduces the size of the discharge and removing the shim increases the size of the discharge.

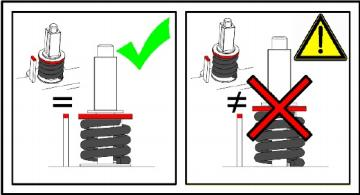

5. Screw the loose square nut back into place, making sure that the ruler plate to the right of the square nut is flush with the top cover plate of the spring to maintain the correct amount of spring compression.

5. Re-insert the safety screws, making sure they go through the threaded rod holes, and re-tighten the storage tank cover.

For specific operations, you can refer to the following video.

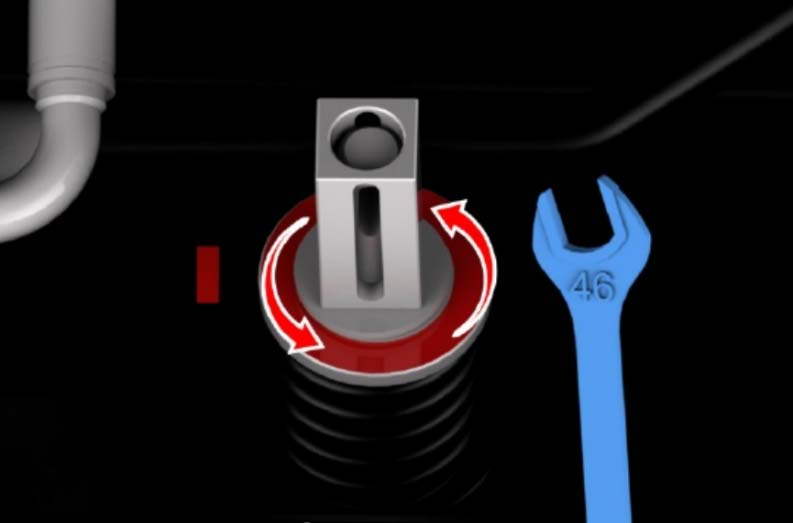

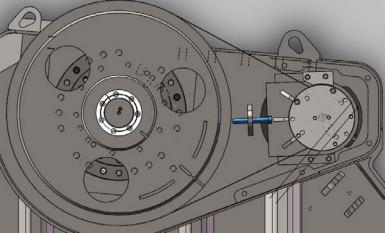

How to adjust the rotation speed?

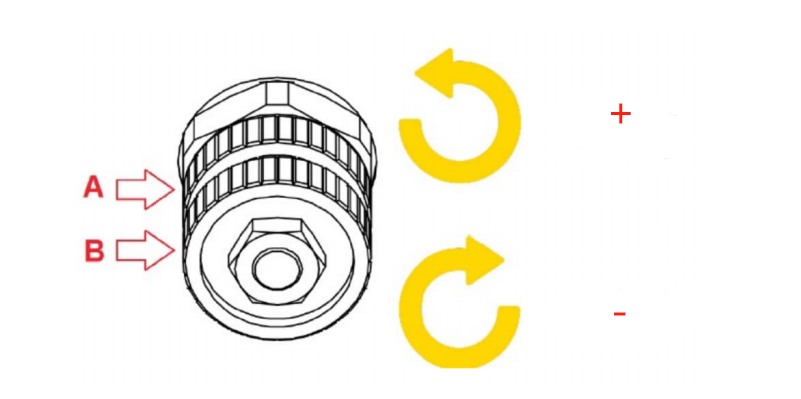

Generally, the speed of this crusher buckets is in the range of 345 to 355 RPM. adjustments may be necessary to achieve better performance levels, depending on the material being crushed, or to reduce vibration.

To adjust the speed, loosen the inner lock washer (A) counterclockwise to increase the speed and turn the outer handwheel (B) clockwise to decrease the speed. When adjustment is complete, block the handwheel with the sleeve seal.

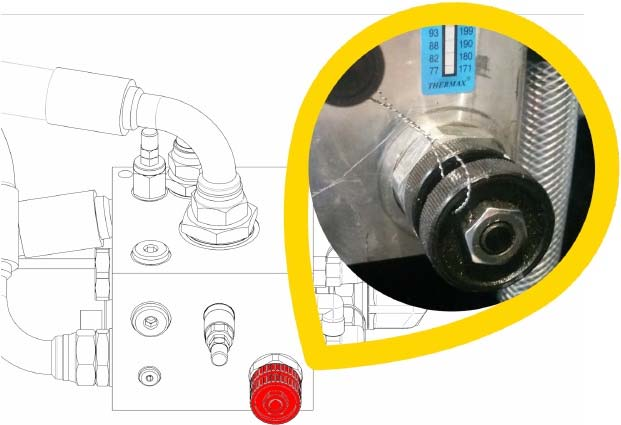

To further confirm the number of revolutions of the crushing hopper, an accurate measurement was taken using a rotational speed sensor, as shown below.

What to do when a crusher bucket gets stuck?

When material is inside the crusher bucket and becomes jammed, place the bucket vertically, with the front edge plate facing down, and gently tap the floor until the jammed material falls out of the opening (see diagram). The operator must not personally or manually remove any material jammed inside the bucket.

Step:

- Stopping the movable jaws

- Place the crusher buckets vertically with the front plate facing downwards.

- Tap the ground gently to unload the material in the bucket crusher.

- If necessary, gently rock the bucket crusher to its limit position.

Attention: If the machine jams, it is strictly forbidden to strike the crusher buckets horizontally against the ground or against an object. The manufacturer declines all responsibility for any damage caused by this operation.

What are the do’s and don’ts of crusher bucket operation?

The operator must avoid using the crusher buckets under unsuitable conditions or under the influence of alcohol or drugs.

In order to safeguard the health and safety of workers, it is recommended that the workplace be set up so that the excavator can be placed higher than the material to be crushed; this reduces the radius of the load and avoids the need to reach the maximum working radius configuration.

When used on an excavator, it is recommended to avoid the bucket loading stage with the trolley on its side (see figure below right). A sideways-mounted carriage is more unstable than a straight carriage (see below, left).

Never operate the excavator with the engine idling while working. Maintain engine speed so that the hydraulic fluid can circulate at the proper pressure.

Crusher buckets are used to crush or reduce the size of the object to be crushed. In this regard, it should be noted that hard materials such as granite, porphyry, etc. are permitted to be crushed, but should not be sized more than 50 per cent of the opening of the crushing hopper.

Please note that the jaws will wear out faster than and all other consumable components; furthermore, to ensure a long life of the jaws, it is recommended to avoid crushing wet materials. For removal of semi-hard materials, the size should not exceed 70% of the opening of the crushing hopper. If the above requirements are not met, complete jamming of the upper and lower jaws may occur.

Special Attention:

How to make the Maintenance for crusher buckets?

Special guidelines

- All inspections, cleaning and maintenance operations must be carried out in the shutdown mode.

- Removing or tampering with the machine’s protective devices is strictly prohibited.

- Before carrying out any inspection, cleaning or maintenance operation, the operator must wear personal protective equipment suitable for that operation

- If any safety part of the machine is damaged or faulty, it must be replaced immediately

- Maintenance operations must be carried out by qualified personnel who must avoid using the crushing hopper in unsuitable conditions and under the influence of alcohol or drugs.

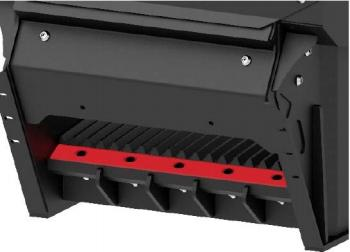

1. Upper and lower jaw plate platen

A pressure plate holds the upper and lower jaws in place. It is fastened by bolts and nuts, which may loosen due to the beginning stage of crushing vibration.

For the first installation, the screws need to be tightened repeatedly. During the second, fourth and eighth hours of actual operation, tighten them once each until the jaws are completely fixed.

After this time, the screws must be checked regularly, and it is recommended that the platen and its bolts and nuts be inspected every 40 hours as they are considered to be parts prone to wear. If damaged, they will not keep the jaws in the correct position and must be replaced immediately.

For the first installation, the screws need to be tightened repeatedly. During the second, fourth and eighth hours of actual operation, tighten them once each until the jaws are completely fixed.

Platen recommended replacement cycle: every 500-2000 hours

2. Pulleys

Pulleys are attached to both ends of the motion system shaft. Be sure that the indicator bars are always aligned, otherwise problems such as abnormal vibration of the entire machine or damage to the spindle system occur. Also periodically check that the expansion sleeve socket head cap screws are always properly tightened.

Normal inspection cycle: every 200 hours or if vibration abnormality occurs

3. Leather Belt

Belts are used to connect the motor pulley to the large pulley to transfer power. Belts wear out gradually as they work, and the effects of wear are:

Recommended belt replacement interval: every 1000-2000 hours

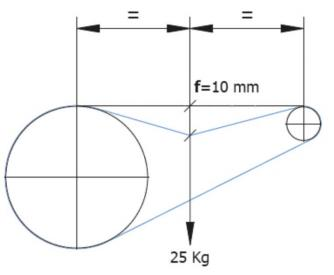

To verify that the belt is correctly tensioned, apply a 25kg weight to the centre point of the axis between the two pulleys. The belt is properly tensioned when there is a 10mm amount of compression deformation.

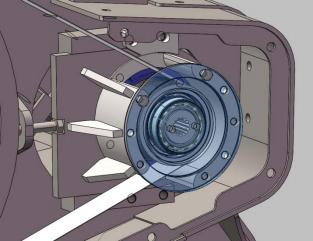

4. Motor drive unit

The motor drive unit is an important part of the power transmission, with internal motor pulleys, bearings and other parts, of which the motor pulleys and belts have motion transmission, so there is normal wear and tear. When abnormal noise, vibration, belt jumping, etc. occurs, the internal bearing or other parts are worn out and need to replace the corresponding parts.

The motor turns the hydraulic pressure of an excavator or loader or other power equipment into mechanical energy. Therefore, the system that powers the equipment determines its good functioning as well as its potential for failure or damage.

Recommended bearing replacement cycle: every 1000-1500 hours

5. Spring damping units

The spring unit is an important vibration-damping unit that connects the movable jaw to the frame and is an important component. Of particular importance are the following: The spring is a shock absorber that supports the weight of the movable jaw. Ensure that the square nut right finger rule plate is flush with the spring top cover plate.

Recommended spring replacement cycle: every 500-1500 hours

Damping sleeve recommended replacement cycle: every 500-1500 hours

6. Elbow board

The elbow plate is located between the movable jaw and the frame and is used to guide the movement of the movable jaw. However, when the machine is overloaded, the elbow plate wears out or breaks, thus protecting the whole machine. Therefore the elbow plate is the insurance unit of the whole machine.

CAUTION!!!

When the spring is loose, uncompressed or broken, the elbow plate will not fit tightly into the frame, resulting in the elbow plate being more susceptible to damage or the elbow plate coming out of the frame. Or cause the frame to take more of a beating and make the frame abnormal, possibly with even more serious consequences.

7. Movable jaw

Crusher bucket jaws are designed to provide optimum performance and the widest range of materials to be crushed. Their wear is inevitably related to the type of material they come into contact with. It depends mainly on:

- Infeed and Output Sizes

- Physical properties of materials

- Chemical composition of materials

- External environment

- Operator’s skills

The upper and lower jaws are interchangeable. This makes it easy for you to:

When the movable jaws are worn, replace the fixed jaws with movable jaws. Or rotate 180° so that the least worn part is at the inlet. When rotating one jaw 180°, the other jaw must be rotated if the distance between them reaches a point where there is a danger of collision with the tops of the teeth.

The jaws must be replaced when the height of the teeth of the jaws has been reduced by wear to less than 10 mm and at more than 40 per cent of the surface levelling. Failure to replace it in a timely manner will result in the generation of forces beyond those borne by the frame, leading to potentially serious consequences.

Suggested replacement cycle of jaw plate: wearing parts, according to the actual working conditions replacement.